ENSEPATEC products

Intake Filtration Systems

ENSEPATEC RainSep - Air/Liquid Separators

RainSep air/liquid separators from ENSEPATEC provide maximum protection against intake of rain, mist and most fog from wetting out downstream equipment and filters. Wetted filters will increase pressure loss and reduce the efficiency and life of the filters. Keeping your filter dry will ensure maximum performance and life of the filters minimizing maintenance cost and cost of operating the equipment.

ENSEPATEC SaltSep - Salt Removal & Corrosion Prevention

Salt particles, either solved in liquid or as dry crystalline state are the most unwelcomed visitors for your ambient air intakes and downstream equipment. If not controlled they will reduce the life of the duct system and downstream equipment due to their highly corrosive effects. Air-borne salt laden droplets are too small (1µm to appr. 600µm) to be completely eliminated with a single stage system. For efficient protection against salt a minimum of 2 stages (vane type separator + coalescer / vane type separator + fine filter) is required.

Sand Removal and Filter Protection

SandSep is a protection of GAS TURBINE and ENGINE ROOM air intakes against the undesired ingress of flying sand in desert climates or in a marine environment that is exposed to sand storms. Airborne sand particles plug coarse filters within minutes, causing physical damage to the filters or causing a complete exchange. Under harsh conditions the amount of sand often exceeds 100 kg/m²h. Depending on the prevailing weather conditions, dust storms can be present for only a couple of days per month.

Process Internals

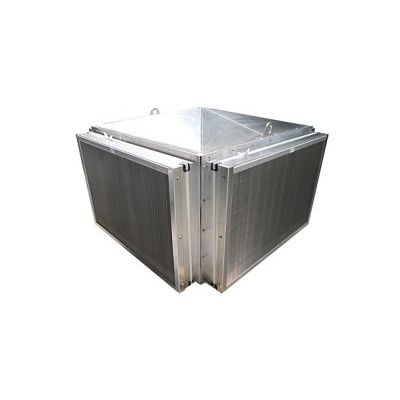

ENSEPATEC - Internals for Horizontal Flow

Ensepatec offers a broad selection of high performance separation internals for horizontal gas flows. These serve in a broad range of industrial, commercial and process applications.

ENSEPATEC - Internals for Wet Scrubbers and Evaporators

Ensepatec offers fully standardized, high-performance and energy-friendly, gas/liquid separations for vertical gas flows. The separators include designs for pre-separation (bulk entrain ment separation for 2-stage systems) and fine separation (to be used as a polishing stage for 2-stage systems or where the process conditions only require a single-stage device). The separators eliminate liquid carry-over caused by high gas velocities to protect downstream equipment and ducting against unwanted effects or corrosion, contamination, or pollution caused by the liquid droplet carryover. These separators have a very low pressure loss and can be operated at gas velocities up to 4.5m/s (900 fpm) under atmospheric conditions, allowing for a mal-distribution of the gas stream up to ±30%.

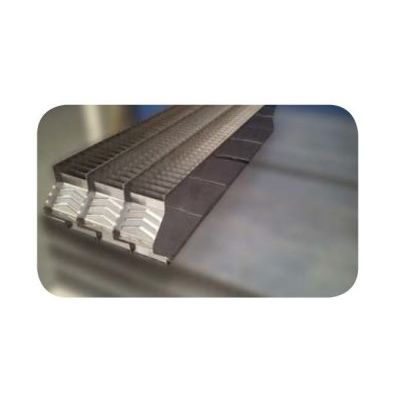

ENSEPATEC - Mechanical Pre- and Fine Separators

Ensepatec provides enhanced liquid/gas separation equipment for the safe and economical removal of liquid droplets from saturated steam inside a steam drum. The separation internals consist out of pre- and fine separation elements including axial and radial cyclones, flow distributors, vane type separators with coalescer pads for the removal of very fine droplets. Ensepatec designs and selects a suitable combination of separation elements depending on the design parameters including internal drum diameter, the specified liquid levels and the allowable pressure loss. Upon request, Ensepatec conducts computational fluid-dynamics to verify steam flow distribution patterns.

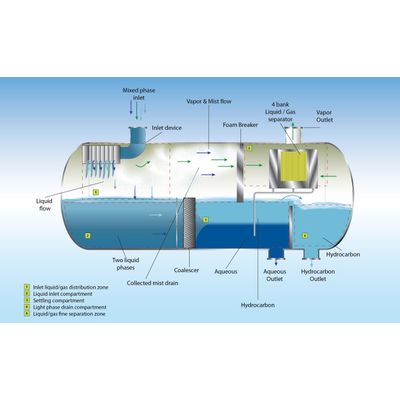

ENSEPATEC - Liquid/Liquid/Gas Separation internals

Ensepatec provides the engineering and design of 3-phase separator internals that target high gas volumes and primary L/L dispersions. Our scope includes the design, engineering and delivery of a) The inlet gas distributor (1). b) The foam breaker along with the the L/G separator (5). c) The dimensional design of the inlet compartmeent, the settling compartment and the product outlet compartment (2), (3), (4). d) The separation of the aqueous and hydrocarbon liquid phases utilizing ether plate pack type or wire mesh coalescers (3). .

Horizontal Separators

ENSEPATEC - Horizontal Knock-out Drum

The horizontal knock-out drum targets at applications with high liquid loads and fine removal efficiencies between 5 and 20µm. The length is dictated by the internal diameter (ID), the gas volume flow and the required efficiency. The horizontal KO-drum accommodates internals such as inlet gas distributors, perforated plates, vane type separators and coalescing pads. The separator is split into 3 zones of different functions.

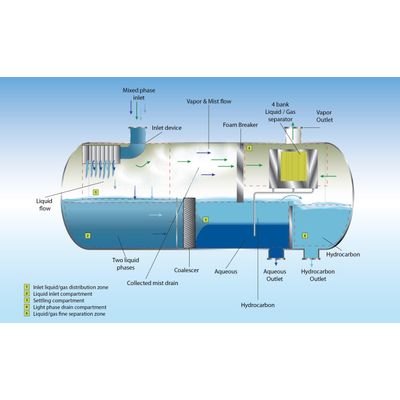

Liquid/Liquid/Gas Separation internals

Ensepatec provides the engineering and design of 3-phase separator internals that target high gas volumes and primary L/L dispersions.. . Our scope includes the design, engineering and delivery of. a) The inlet gas distributor (1). b) The foam breaker along with the the L/G separator (5). c) The dimensional design of the inlet compartmeent, the settling compartment and the product outlet compartment (2), (3), (4). d) The separation of the aqueous and hydrocarbon liquid phases utilizing ether plate pack type or wire mesh coalescers (3). .