ESR International LLC products

Model Trial on Municipal Solid Waste - Landfill Avoidance

The final challenge that ESR must face lies in the total elimination of landfill, and this brings us back to a trial that was conducted in Belgium in 1996 on 30,000 tons of MSW. This waste contained everything but food and garden waste, paper and cardboard. The results of this trial were fairly amazing: the floats of the 1.25 separator yielded an organic fraction of a calorific content >12,000 BTU/lbs, while the recovery of high-grade secondary aluminum was as high as 7.5%.

Source Separation of Food Waste

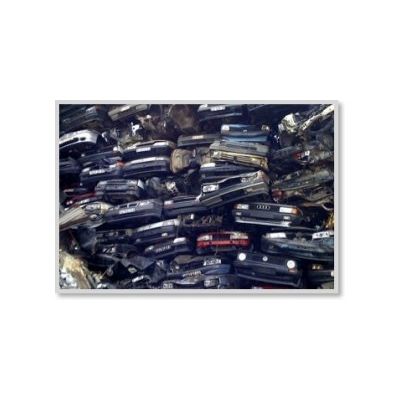

Therefore, if food waste is kept source separate, a junk automobile and a trash bin present themselves to the ESR dense medium separators in roughly the same manner. If a complete set of ESR separators can process the non-ferrous residue of as many as 750 automobiles per hour, the same phenomenal tonnages are easily accomplished with respect to MSW. A single set of ESR separators could handle the entirety of the MSW stream of any large US, Japanese or European city. Once food waste is kept source separate and recycled at its source, the remainder of the garbage bin can pass through the ESR separation process with the ease and efficiency of an automobile, a television set or an outdated computer. Once food waste is kept source separate and recycled at its source, it is easy to imagine a world in which landfills are completely eliminated.

Far Cheaper to Avoid Landfill Than to Create It

Minimal source separation, together with dense medium separation, together with the bioconversion of putrescent organic waste, together with the thermal conversion of non-putrescent organic waste (either cement kilns or gasifiers), allow us to recycle virtually all of the waste normally destined for landfill. Even the non-metallic inorganic material isolated by this dense medium process can profitably serve as a low grade aggregate. When the infrastructure needed to implement this strategy is well established, we should not be surprised to discover that it is far cheaper, even in the short term, to avoid landfill than to create it. A landfill is undoubtedly one of the worst things we can pass on to future generations. Surely this dangerous and inherently evil activity has to stop.

The Future is Now

Most municipalities throughout the world acknowledge the importance of landfill elimination, but very few realize that all of the essential elements needed to make this happen are already in place. A future in which everything is recycled and landfill is eliminated does not lie 100, 50 or even 20 years down the road. The future is now. It has already arrived.

Recycling

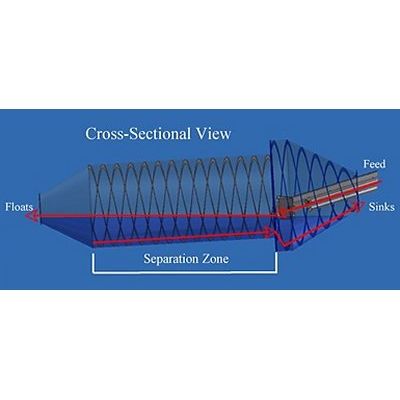

Dense medium separation

ESR International LLC patented a unique bi-directional dense medium barrel that proved to be the most accurate dense medium separator ever employed in the separation of a variety of materials ranging from carrots and potatoes to plastics and non-ferrous metals (US patent 5,373,946 of Dec 20, 1994). This invention was further supported by two additional patents: US patent 5,495,949 of March 5, 1996 and US patent 6,024,226 of Feb 15, 2000.

Esr`s Bi-Directional Barrel

Twenty years ago all dense medium (DM) separators on the market were mono-directional, with floats and sinks reporting on the same side of a relatively short horizontal drum. This concept fails for four basic reasons.