Exelliq Austria GmbH products

Extrusion Lines

Exelliq - Digital Extrusion System

Exelliq's DIGI.LINE is a cutting-edge digital extrusion system designed to enhance profile production through advanced digitalisation and automation. This system optimises real-time extrusion processes, ensuring increased output while minimising material consumption. Key features include DIGI.CONTROL, a networked control unit that manages the entire extrusion process, and FLOW.MATIC, which ensures precise profile geometry without manual intervention. The DIGI.LINE utilises SHAPE.MATIC technology to automatically maintain profile consistency through adaptive water and vacuum settings. Integrated with WEIGHT.MATIC, it enables precise in-line weighing for material saving, further boosting production efficiency. Exelliq's decades of expertise in profile tools and extrusion lines are encapsulated in DIGI.LINE, offering reliable performance and a competitive edge. Consistent with modern Industry 4.0 standards, DIGI.LINE represents a significant stride forward in extrusion technology.Exelliq - Extrusion System

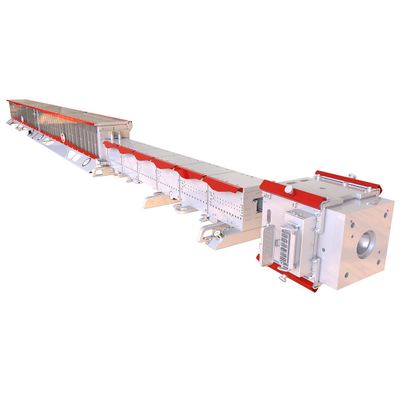

The Exelliq RED.LINE is a premium extrusion line designed to enhance productivity, process reliability, and energy efficiency. Fine-tuned to the RED.TOOLING system, it provides superior performance in plastic profile extrusion. Equipped with a PLC control and touch panel interface, the system incorporates Exelliq's energy-saving GESS.TRONIC system, achieving significant reductions in energy and water usage. The RED.LINE can operate as dual-strand constructions, compatible with Exelliq’s product lineup. It includes advanced features like the RED.CAL module for water and energy savings and the FLOW.CONTROL for precise material savings. The RED.LINE system supports various configurations, including single and twin-strand builds, with calibration tables up to 28 meters. Its design prioritizes ease of maintenance and operational efficiency, offering features like vacuum management and ergonomic interfaces, suitable for high-demand industrial applications.Extrusion Lines - Extrusion Systems

Exelliq - Digital Extrusion System

Digitalisation must deliver measurable value. DIGI.LINE confirms this in the harsh production environment of extrusion. DIGI.LINE minimises material consumption and increases output. Additionally, it boosts consistency and production reliability in extrusion.

Exelliq - Extrusion System

The RED.LINE is a premium extrusion line with which you can achieve higher productivity, utmost process reliability and energy savings. It is perfectly tuned to the RED.TOOLING system.

Plastic Extrusion Tooling

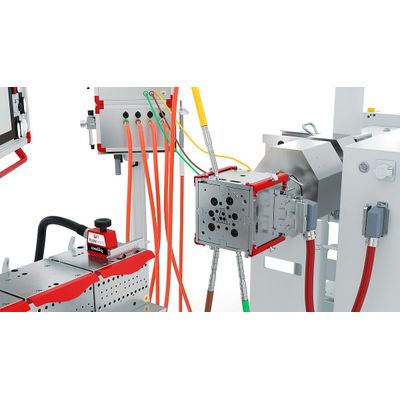

Exelliq - Digital Profile Extrusion Tooling System

DIGI.TOOLING - the digital profile extrusion tooling does not require any hoses and is designed for the highest possible degree of automation and efficiency. The innovative TOOLING.PALLET system guarantees fast set-up times and error-free retooling. In addition, DIGI.TANK allows for the water level, water flow rate and vacuum settings to be controlled automatically.

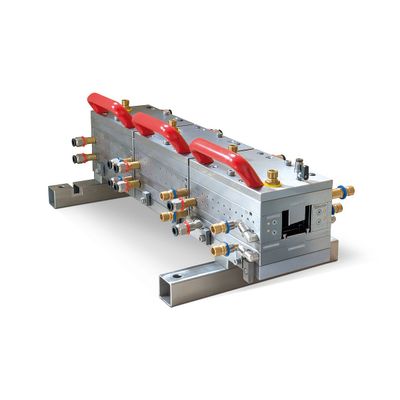

Exelliq - Plastic Extrusion Tooling System

Ahead through superior profile quality and low operating costs. RED.TOOLING meets the highest requirements in profile extrusion and is setting new standards with its unique features such as a heater cage with a central plug, PDC technology, roller short calibration or options like FLOW.CONTROL, FLOW.MATIC, air support control,roller tuner, and the KEEP.CLEAN unit.

Exelliq - Modular Extrusion Tooling System

MPT.TOOLING is the result of decades of experience and incorporates the know-how of thousands of high-performance extrusion toolings built by Exelliq. The design is lean and trimmed to the essentials; however, the core elements of Exelliq’s high-end tooling technology are still included. Moreover, you have the option to upgrade MPT.TOOLING further with a variety of options and special features.

Tooling

Exelliq - Digital Profile Extrusion Tooling System

DIGI.TOOLING by Exelliq is a sophisticated digital profile extrusion tooling system, designed to enhance efficiency and precision in extrusion processes. It is built to integrate seamlessly into high-level automation environments, eliminating the need for conventional hoses. This advanced system includes the TOOLING.PALLET, which facilitates rapid setup and error-free retooling. The DIGI.TANK component allows for automatic regulation of water level, water flow rate, and vacuum settings, ensuring reliable consistency in profile geometry. Key features such as FLOW.CONTROL and FLOW.MATIC technologies offer precise control over melt flow directly within the die, maintaining consistent profile dimensions while keeping material use close to the lowest weight tolerance. The DIGI.TOOLING die, compatible with these features, is engineered for exact geometries and functional profile sections. Altogether, these technologies minimize setup errors and optimize extrusion line performance for high-repeatability operations.Exelliq - Advanced Profile Extrusion Tooling

RED.TOOLING sets new standards in the profile extrusion industry by offering premium tooling that ensures high-quality output and low operating costs. The technology incorporates unique features such as a heater cage with a central plug, which enhances safety and productivity, along with PDC technology for improved process reliability and minimized quality fluctuations. RED.TOOLING excels in various applications with its innovative features like roller short calibrations, FLOW.CONTROL, and the KEEP.CLEAN unit, which collectively contribute to reduced resource consumption and decision support for service upgrades. The tooling's dry calibration option effectively utilizes water and energy, balancing cooling efficiency without sacrificing quality. RED.TOOLING's roller short calibrations significantly diminish surface scratches, while the vacuum tank minimizes water utilization. These features offer considerable savings in energy costs and material inputs, addressing both economic and environmental efficiency in extrusion processes.Automation

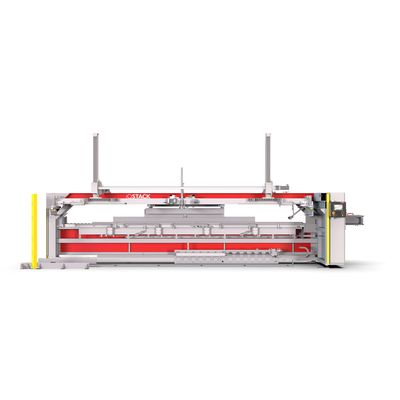

Exelliq - Automated Stacking System

The iQ STACK Automated Stacking System by Exelliq represents an advanced solution designed for seamless integration into existing extrusion lines, facilitating a move towards fully automated production processes. This system enables the precise automatic handling of profile bars post-cut, systematically placing them into profile racks according to a predefined stacking pattern. The technology addresses labor shortages by minimizing the need for manual intervention at the extrusion line`s conclusion and ensures a smooth workflow from production to warehouse. Designed with innovation at its core, iQ STACK increases efficiency by streamlining operations and enhancing the value added throughout the extrusion process. As part of Exelliq`s comprehensive product suite, this system exemplifies their commitment to digitalization, automation, and continuous operational improvement.