FENN products

Metal Forming Machinery

FENN - Rolling Mills Machinery

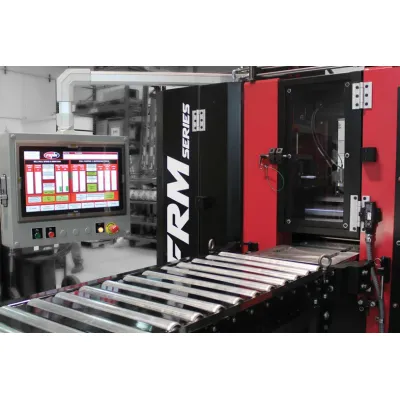

FENN Rolling Mills for any application up to 3.3 million lbs. (1500 MT) separating force. Different Configurations available for Maximum Efficiency: FENN engineers and manufactures a complete line of precision rolling mill machines, offering a wide range of standard and custom rolling mills for a variety of applications. These rolling mill applications include heavy ingot breakdown, laboratory research, coil-to-coil rolling, and precision strips. Our rolling mills are available in 2Hi and 4Hi roll configurations. Mills may be either work roll-driven, back-up roll-driven, or a combination of both. 4HI mills with work rolls are offered as small as .500″ (12.7mm) in diameter, 2HI mills are offered with rolls up to 16″ (400mm) in diameter

FENN - Wire Flattening & Shaping Lines

High-speed lines that can meet aggressive machine production requirements. Achieving up to 3,000 feet per minute (15.25 mps). FENN has led quality wire flattening and shaping machinery for over 120 years. Our experts take the time to design and build suitable machines to fit your specifications and fulfill your unique production requirements. With experience building standard metal forming equipment and customized metal forming machinery solutions, FENN’s product and service offerings can help increase precision and productivity for your business. Many industries across various applications trust FENN for their wire-shaping mills. We will design an effective combination of equipment to accurately and economically produce your product. From the machine’s conception and design to creating a pass schedule, developing the appropriate rolls, and implementing the proper measuring equipment, we will ensure your project is handled expertly from beginning to end. Contact us today to start a conversation and learn how quickly and accurately you can produce shaped wire!

Metal Forming Machinery - Swagers

FENN - Stationary Swagers

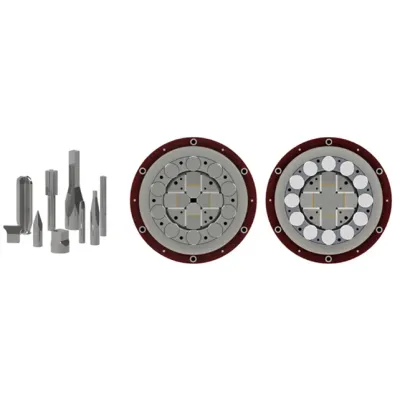

Complete parts can be made from entry rounds, squares, or rectangles—hot or cold. Types include simultaneous blow used to create fluted shapes and cross-circular sections and alternate blow used to create rectangular shapes, squares, and hexagons. This method is capable of any cross-section other than a perfect circle. During stationary die swaging, the spindle assembly remains stationary, and the roller cage rotates. Shown left to right: Stationary Swagers, Alternate Blow, Simultaneous Blow.

FENN - Rotary Swagers

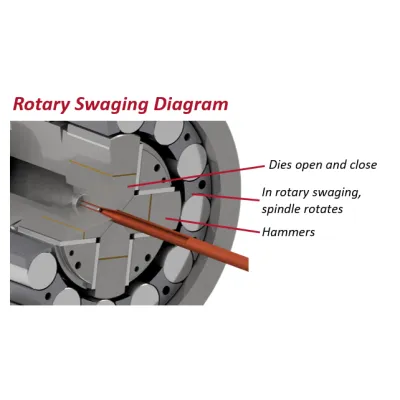

During rotary swaging, forming dies back by hammer blocks revolve around the workpiece. As the spindle revolves, centrifugal force throws the hammers and dies outwards against a series of rollers surrounding the spindle. Each time the hammer blocks strike diametrically opposed rolled, they are driven inward – causing the die halves to close and compress the metal being swaged. Examples include cartridge heaters, hypodermic tubing, piping, armaments, and logging industry applications.