FENN - Rolling Mills Machinery

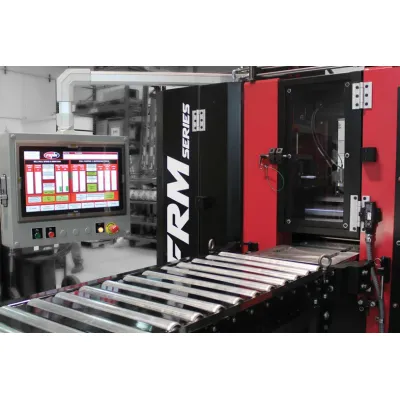

FENN Rolling Mills for any application up to 3.3 million lbs. (1500 MT) separating force. Different Configurations available for Maximum Efficiency: FENN engineers and manufactures a complete line of precision rolling mill machines, offering a wide range of standard and custom rolling mills for a variety of applications. These rolling mill applications include heavy ingot breakdown, laboratory research, coil-to-coil rolling, and precision strips. Our rolling mills are available in 2Hi and 4Hi roll configurations. Mills may be either work roll-driven, back-up roll-driven, or a combination of both. 4HI mills with work rolls are offered as small as .500″ (12.7mm) in diameter, 2HI mills are offered with rolls up to 16″ (400mm) in diameter

FENN Rolling Mills are engineered to meet the critical requirements of metallurgical research and applications up to 3.3 million pounds (1500 MT) separating force. FENN designs and builds rolling mills that are available with a complete offering of material handling options, processing, gauging, and labor-saving accessories. FENN offers customizable rolling mills for processing ferrous, non-ferrous, alloy, exotic, and engineered metals for production and laboratory applications.

FENN offers hot and cold milling machinery and combination mills that can accommodate both hot and cold rolling applications. Hot rolling is a process in which metal heats above the recrystallization temperature, allowing the material to deform on a microscopic level and take its new shape. Cold rolling is when the process is conducted at room temperature and does not require heating the metal.

Typical Materials : Type of Mills : Applications

Steel : Research Bonding : Material Research

Copper : Mint : Aerospace

Lead : Powder : Consumer

Aluminum : Hot Rolling : Automotive

Superconducting : Cold Rolling : Military

Exotic Metals : Rod : Renewable Energy

Precious Metals : Strip :

Platinum : Sheet :

Ferrous / Non-Ferrous : Plate :