- Home

- Companies

- Flow Science, Inc.

- Software

Flow Science, Inc. software

Flow Science - High Performance Compute Clusters

FLOW-3D/MP enables engineers to take advantage of the power of FLOW-3D on high-performance compute clusters to tackle problems with very large domains or long runtimes. Hybrid parallelization of the FLOW-3D solver uses both Message Passing Interface (MPI) and OpenMP to achieve maximum parallelization and utilization of the underlying multi-core cluster architecture. FLOW-3D/MP offers significant performance advantage and reduced runtimes which results in shorter design cycles and an opportunity to do a comprehensive parametric study within their design cycles. All this can be achieved while retaining the accuracy offered by FLOW-3D.

Flow Science - Droplet/Bubble Source Model for CFD Software

Flow Science - Advanced Simulation Software

An advanced simulation software, FLOW-3D AM analyzes and predicts melt-pool dynamics and solidification in AM processes such as laser powder bed fusion (LPBF) and directed energy deposition (DED). Built on a robust CFD engine, FLOW-3D AM incorporates high-fidelity solutions for conductive, convective, and radiative heat transfer, laser and particle physics, and Marangoni effects for predicting complex phenomenon at the micro and meso scales.

FLOW-3D CAST

Flow Science - High Pressure Die Casting Workspace

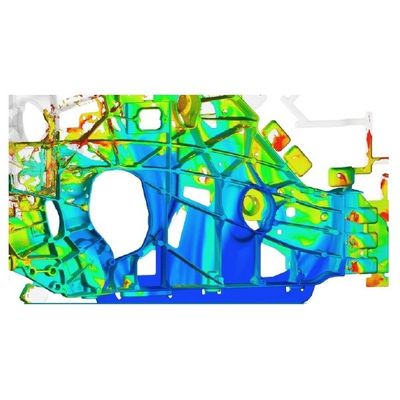

The High Pressure Die Casting Workspace is an intuitive modeling environment designed to help engineers successfully model high pressure die casting applications with FLOW-3D CAST. Full control of shot sleeve motion, combined with advanced die thermal control, machine parameter modeling, and accurate resolution of fill and backpressure conditions make FLOW-3D CAST the reference solution for the most demanding HPDC simulation needs. In addition to advanced porosity prediction and post-processing functionalities, the HPDC Workspace includes a state-of-the-art chemistry-based solidification and material strength model for Al-Si and Al-Cu based alloys.

Flow Science - Tilt Pour Casting Workspace

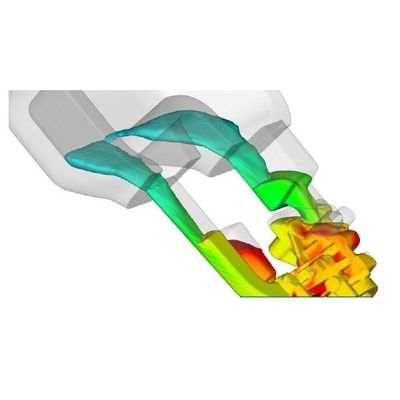

In this FLOW-3D CAST simulation of an 8-cavity tilt pour casting, A356 aluminum is poured at 738 C by rotating the mold from a horizontal orientation to a vertical orientation over 18 seconds. The H13 steel mold is thermally prepared by simulating 5 cycles of fill/solidify/spray cooling using FLOW-3D CAST’s thermal die cycling model.