- Home

- Companies

- FLSmidth A/S

- Products

FLSmidth A/S products

Equipment - Classification

KREBS® gMAX™ - Hydrocyclone

Innovative hydrocyclone design; KREBS gMAX Cyclones incorporate improved geometry enhancing our inlet head, cylinder section, cones and apex. The result? Finer, sharper particle separations and significantly advanced performance for your operation.

KREBS® DeSanders - Desander Cyclones

Solve your fine-particle separation challenges: KREBS DeSanders; Customisable and built to specification to fit your needs and application, KREBS DeSanders also incur a low capital cost. We offer a variety of sizes with different internal fittings, lined or unlined, mounted at any angle, to optimise performance for your operation.

Hydrocyclone Technology - Cyclones

KREBS® - Model CP - Close-Packed Vessels

Keeping a solid focus on your fine-particle separation needs; hen fine particle separation is of utmost importance, only small-diameter cyclones will provide that critical cut point. Our CP (Close-Packed) Vessels use cyclones from 13mm (0.5-in) up to 76mm (3-in) that maximize the unit’s separation abilities and provide a finer cut point than any other cyclone in the industry.

KREBS® - Enhance Cyclones

Improve your cyclones’ performance with CycloStack™ and CycloWash™. Boost your cyclones’ dewatering performance with our CycloStack, which attaches to the bottom of a standard cyclone to automatically control the moisture content and discharge concentration of the cyclone underflow. Enhance cyclones’ separation and desliming capabilities with our patented, low-cost CycloWash device.

KREBS® - Model D-Series - Hydrocyclones

There’s a reason our D-Series Cyclones are found in mining processes. They work! Our D-Series Cyclone is a loyal workhorse in the world of cyclone technology – providing excellent separations, day in and day out keeping your processes running smoothly and less downtime. They are a go-to choice for your mining and industrial applications.

KREBS® - Radial Manifold Systems

Enhance your hydrocyclone performance with the proper manifold system. Cyclone performance does not always correlate to size. A cyclone is providing proper separation might require additional capacity, installing a larger cyclone is not the answer, as performance will drop. Instead, add a manifold with two or more cyclones; you will effectively increase capacity at the desired separation.

KREBS® - Model Manifolds - Cyclones

KREBS® - Pulp Cleaner

Efficiently remove contaminants from your paper pulp; Remove dense debris from paper pulp with our high-efficiency pulp-cleaning cyclones. Our continuous rejects cleaners, typically installed in multiple stages, remove fine sand from paper pulp. Intermittent rejects cleaners collect larger reject material and discharge it intermittently to minimise fibre loss.

KREBS® gMAX® - Urethane Cyclones

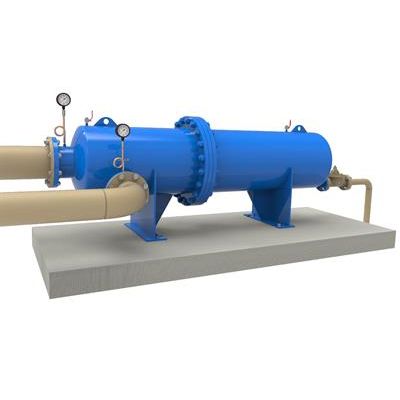

Performance and longevity: benefit from both with Urethane Cyclones; Most separation equipment demands you make a choice. You end up sacrificing production, wear life and even end product quality looking for the best solution to your wet processing needs. Our Urethane Cyclones are different. You gain the best of all worlds from capital outlay to capacity to quality to long wear life. Ease of installation is facilitated by our lower weight construction. Performance is guaranteed by improved geometry and long wear life.KREBS® CycloClean - Deoiler Cyclone Vessel System

The best deoiler system you will ever use While it’s true that oil and water don’t mix, finding an effective and efficient system to separate the two liquids is not so easy. That is where the KREBS DeOiler Vessel steps in. Compact, consistent and incredibly low-maintenance, this proven hydrocyclone system removes hydrocarbons, regardless of flow rate.