- Home

- Companies

- FLSmidth A/S

- Products

- KREBS® - Model CP - Close-Packed ...

KREBS® - Model CP -Close-Packed Vessels

Keeping a solid focus on your fine-particle separation needs; hen fine particle separation is of utmost importance, only small-diameter cyclones will provide that critical cut point. Our CP (Close-Packed) Vessels use cyclones from 13mm (0.5-in) up to 76mm (3-in) that maximize the unit’s separation abilities and provide a finer cut point than any other cyclone in the industry.

Simply effective: Industrial desander vessels for fine separation

In a market where numerous industries require separation of fine solids from liquid matter and each situation is unique, we know your solution needs to be thorough and complete. At FLSmidth, we keep a solid (and fluid) focus on hydrocyclone applications throughout all phases of separation.

In a market where numerous industries require separation of fine solids from liquid matter and each situation is unique, we know your solution needs to be thorough and complete. At FLSmidth, we keep a solid (and fluid) focus on hydrocyclone applications throughout all phases of separation.

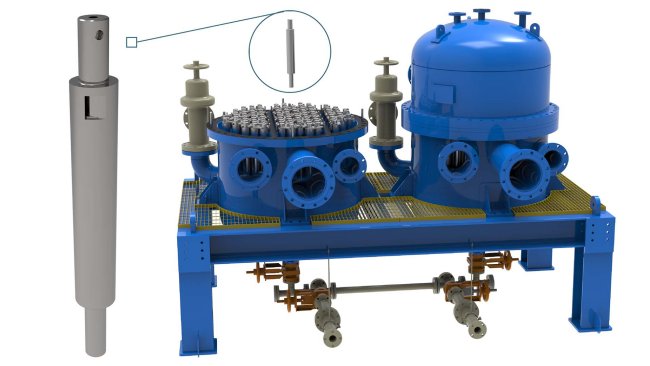

KREBS CP Vessels, in a nutshell, are simply pressurized containers that hold from a few up to hundreds of small, high-capacity cyclones. As a system, the vessel uniformly distributes the feed with one feed inlet, and collects the overflow and underflow with one outlet for each. The hydrocyclones are closely packed inside a three-chamber vessel, with stainless steel plates separating the overflow and underflow from the feed chamber.

It all boils down to separation

Our customers always ask about separation. And we tell them our CP Vessels can make separations as fine as 5 microns, depending on their slurry characteristics.

Typically, we talk in terms of D98, or the point where 98% of solids at a certain size are removed. For example, at an inlet concentration of 1% solids with sand and water, our 50mm (2-in) gMAX Cyclone will remove 98% of 2.65-specific-gravity solids that are 12 microns and larger.

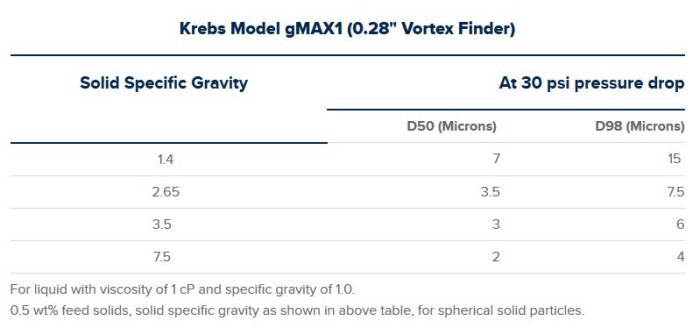

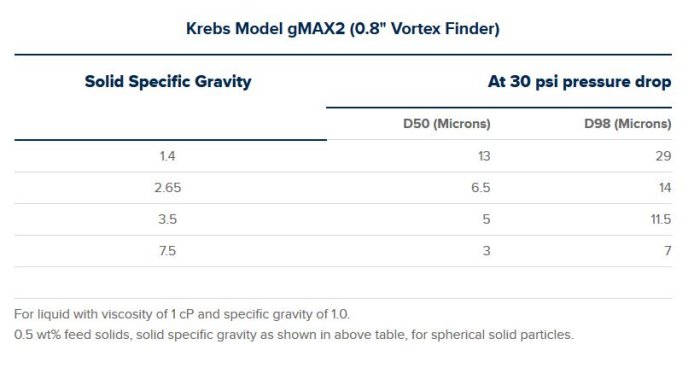

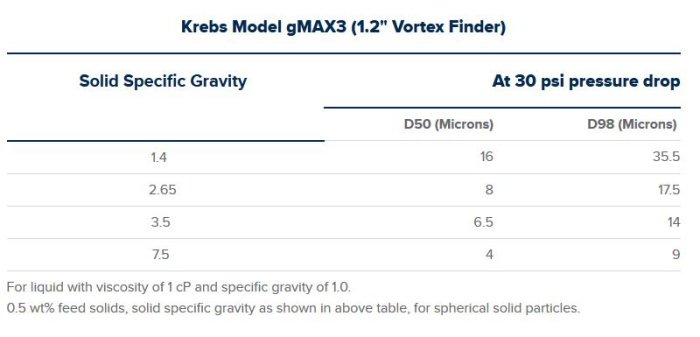

Sample separation capabilities

High-capacity desander vessels in a small footprint

- Efficient, versatile separation of very fine solids

Small-diameter cyclones maximize our unit’s separation abilities to efficiently remove very fine solids. The advantage we provide is a finer cut point than other cyclones can achieve. The features that back up these advantages include a redesigned inlet that separates solids as they enter our hydrocyclone, and a patented double cone angle, which keeps fine solids in high velocity areas, preventing them from exiting the cyclone overflow. - Low capital cost, small footprint

CP Vessels are extremely compact, as compared to an external manifold system configuration. This reduces your capital outlay and installation headaches. - Easy operation, easy maintenance

The system is simple to operate, as it has no moving parts. By combining our world-class gMAX separation technology with an optimal maintenance design, we have created a system that is easy, fast and safe for removal, replacement and cleaning the vessel.

The power of many cyclones in one simple vessel

KREBS CP Vessels comprise a system of compact, high-capacity, centrifugal separator cyclones, designed to efficiently separate fine solid particles from liquid.

The vessel accommodates many individual hydrocyclones, each uniformly fed using one common feed nozzle, providing consistent operation of all units. The system includes a single feed inlet, and single overflow and underflow outlets.

Cyclones used within the CP Vessels range in size from 13 mm to 76 mm (0.5-in to 3-in in diameter, depending upon your application.

Using computer simulation, we are able to accurately predict your desander vessel’s performance, ensuring the ideal system for your application and eliminating the need for onsite testing. Our use of cyclone “blanks” allows for operational flexibility, where flow rates may change from the original design conditions.

We construct CP Vessels of carbon steel and stainless steel as standard. We also build vessels to withstand high temperatures and pressures, and be certified per ASME requirements or specific customer specifications.

CP Vessels have are easy to install and maintain, due to flanged connections and a removable cover for inspection and/or maintenance. We can supply isolation valves at the inlet, if desired, to allow isolation of the vessel for internal inspection. An automatic valve controls discharge of the underflow steam, to purge solids as required.

As an option, CP Vessels can be built with an open underflow. This design allows for easy visual inspection and includes a sloped underflow launder directly attached to the vessel to allow discharge of solids.

Our CP Vessels have a mounting lug design attached to the vessel shell and the design also provides legs. The support saddles are only supplied on the W model Desanders.

- Carbon steel or stainless steel construction is standard

- Variety of construction materials available as an option

- Able to be ASME code-stamped for high temperature and pressure

- Use of cyclone “blanks” allows for operational flexibility where flow rates may change from the original design conditions

- Continuous or intermittent solids discharge

- Assembly tools provided for easy installation or removal of hydrocyclones

- Shipped fully assembled from the factor