Franken Filtertechnik KG products

Phase Separators

Franken - Phase Separator

PT Phase Separators separate fine droplets of d > 0,1 µm. (e. g. caused through thermal effects) from a liquid-liquid dispersion down to the solubility limit.

Franken - Phase Separator

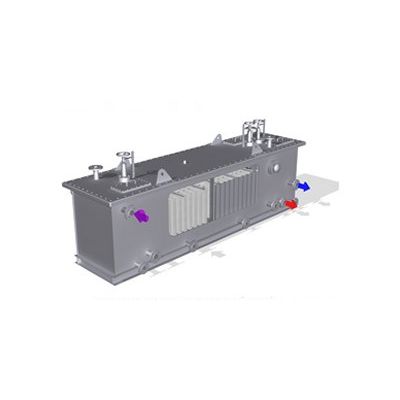

MPT Phase Separators entirely separate droplets of d > 10 µm (e. g. caused through mechanical effects or pumps) from a liquid-liquid dispersion. They can be used in the fields of process technology and waste water treatment. MPT Phase Separators work without pressure loss and can be supplied with pressure vessels or rectangular vessels. No energy and maintenance are required for the operation. In addition, they are available in a variety of materials.

Franken - Phase Separator

PTG Phase Separators separate droplets of d > 50 µm (e. g. caused through agitators/flows) from a liquid-liquid dispersion with high density difference and low viscosity from the main phase. PTG Phase Separators are optimized in terms of flow and residence time. They are used for the coarse pre-separation and as independent phase separator.

Franken - Phase Separator

Separation of acidic aqueous phase from hydrocarbons, vessel coating made of ECTFE.

Franken - Phase Separator

Separation of glycerine phase from methylester after 1st and 2nd transesterification.

Franken - Phase Separator

Separation of oil droplets from ethylene, vessel with design pressure 70 barg.

Franken - Phase Separator

Separation of acidic aqueous phase from a highly viscous polymer solution (>20Q mPas).

Franken - Phase Separator

Separation of paraffin oil from acidic waste water, MPT phase separation stage made of PVDF.

Franken - Phase Separator

Separation of fatty acids from woste water, vessel with integrated heating system.

Reverse Flow Filtration Plants

Franken - Reverse Flow Filtration Plants

FRANKEN Reverse Flow Filtration Systems are a perfect combination of filter technology and expertise in plant construction. Our RF reverse flow filters are engineered to meet the demand for state-of-the-art liquid super filters.This sustainable filter technology is key in enabling us to engineer and build complete plants on the scale which is required. We can also supply all the peripheral equipment the project demands.