GeoSierra LLC - a Cascade Company services

Environment

Permeable Reactive Barriers

GeoSierra`s azimuth controlled injection technology has been used to construct full scale iron permeable reactive barriers (PRBs) from moderate depths (~50 ft bgs) down to significant depth (>180 ft bgs). The injection technology constructs the iron treatment wall from a series of conventionally drilled boreholes along the prescribed wall alignment, with specialized frac casings grouted into the boreholes. The iron treatment wall is constructed by the injection of the iron filings into the frac casings with real time quality assurance monitoring of the injections to quantify the PRB geometry and iron loading densities and validate the wall placement is in accordance with design specifications.

Subsurface Impermeable Barriers (PRBs)

GeoSierra has pioneered the installation of trenchless subsurface permeable reactive barriers (PRBs) for groundwater remediation and has installed kilometers of PRBs at sites throughout the USA. The same technology is used to create a subsurface impermeable barrier, as a freeze wall, or impermeable by grout injection or the injection of a special swellable proppant. The imperable barrier can provide containment of hazardous wastes or as a fluid loss barrier for thermal enhanced oil recovery (EOR) using steam, such as in SAGD (Stream Assisted Gravity Drainage) operations.

Soil Remediation Services

Frac Enhanced Soil Vapor Extraction: GeoSierra has pioneered the use of inclusion propagation using non-invasive fluids to enhance the permeability of low permeable soils for effective Soil Vapor Extraction (SVE). Tight soils are not amenable to conventional SVE due to their low permeability. Installing horizontal sand filled inclusions into these soils significantly increases the soil mass permeability and greatly enhances the radius of influence of the SVE extraction wells. Fracture enhanced SVE significnatly reduces the cost and time to remediate tight soil formations.

Energy

Enhanced Steam-Assisted Gravity Drainage (SAGD)

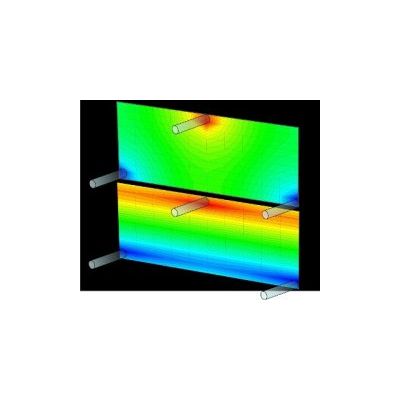

Conventional steam-assisted gravity drainage (SAGD) involves a horizontal well pair typically spaced 5m apart vertically with the injector well located above the producer well as shown. The wells are connected hydraulically during a steam re-circulation phase, followed by the SAGD production mode, i.e. continuous injection of steam and the continuous extraction of liquids. Performance of conventional SAGD can be significantly impacted in formations with low vertical permeability and interbedded mudstone layers impeding vertical drainage and hindering or delaying the startup phase.

Electric Enhanced Oil Recovery ERG

Azi-Frac vertical propped planes filled with an electric conductive permeable 8/20 calcined coke proppant are ideal for enhanced oil recovery by single or three phase electrical resistive heating. The propped inclusions are installed between horizontal wells, between vertical wells or within a single vertical well. A single or three phase alternating current passes through the inclusions, heating the proprietary proppant by resistive heating, which in turn heats the formation, heavy oil or bitumen by conduction.