G.E.P. Valves s.a.s. products

GEP - Steel Gate Valve

Design and Manufacture : API 600 (ISO 10434) or API 6D. Test and Inspection : API 598, API 600 or API 6D. End flange dimension : ASME B16.5 (for NPS24). BW end dimension : ASMEB16.25. Face to face (end to end) : ASMEB16.10. Pressure-temperature ratings : ASMEB16.34.

GEP - Steel Globe Valve

Design and Manufacture: Cast steel globe valve to BS 1873 and ASME 816.34; Forged steel globe valve to API 602. Inspection and Test: API 598. End flange dimension: ASMEB16.5. BW end dimension: ASMEB16.25. Socket-weld dimension: ASMEB16.11 Face to tace and end to end: ASMEB 16.10. Pressure-temperature ratings: ASMEB16.34.

GEP - Steel Check Valve

Design and Manufacture : Cast steel check valve to BS 1868, ASME B16.34 and API 6D; Forged steel check valve to API 602. Inspection and Test : API 598 or API 6D. End flange dimension : ASME B16.5 (for NPS < 24); ASME B 16.47 series B, API 605 or ASME B16.47 series A, MSSSP-44(forNPS>24). BW end dimension : ASME B16.25. Socket-weld dimension: ASME B16.11. Face to tace and end to end: ASME B 16.10. Wall thickness dimension: API 600 and BS 1868.

GEP - Forged Steel Valve

Forged steel valves are available in three types of body-bonnet connection. The first design is the bolted bonnet, with male-female joint, spiral wound gasket, made in F304L/ graphite. Ring joint gasket are also available on request. The second design is the welded bonnet, with a threaded and seal welded joint.

GEP - Floating Ball Valve

Design and Manufacture : API 6D, ASME B16.34 (BS5351), API 608, MSS-SP-72. Face to face Dimension : ASME B16.10, API 6D. Flange Connection Dimension : ASME B16.5. BW Connection Dimension : ASME B16.25. Fire-safe Design : API 607/6FA. Anti-static Design & anti Blow-out Stem : ASMEB16.34.

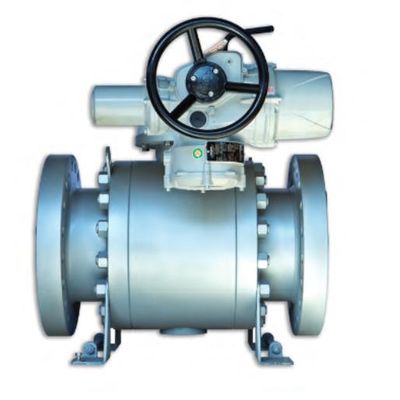

GEP - Trunnion Ball Valves

Design and Manufacture: API 60, ASME B16.34.{BS5351), API 608, MSS-SP-72. Face to face Dimension: ASMEB16.10.AP16D. Flange Connection Dimension: ASME B16.5, NPS>26`) PER as ASME B16.47. BW Connection Dimension: ASME B16.25. Test and Inspection: API 598, API 60. Fire-safe Design: API 607/6FA. Anti-statk Design & anti Blow-out Stem.

GEP - Metal to Metal Sealed Ball Valve

fhe seat material of general purpose bal valve employs generaly non-metal material, such as PTFE. limited by the seat material, the general purpose bal valve can not be used in case of high temperature application, and application medium with solid articles, and ash dregs neither. So, the application scope of general purpose bal valve is restricted partially. TaJong this into consideration, G.E.P Valves is able to offer a ful range of metal to metal seated bal valve, inducting floating ball valve and trunnion ball vafve, which have found extensive appficabons in such industries as petroleum, chemistry, power, metallurgy, and light industry.

GEP - Metal to Metal Sealed Trunnion Ball Valve

Refcc lo twt of trunnion bal valve for main stits and weights of metal to metal sealed trunnion ball valve, of which the flange dimensions and face to face dimensions arc the same as that of trunnion ball valve.

GEP - Female Threaded Ball Valves

Female threaded ball valves are suitable for use on ppctm* of mixium or low pruiurt to turn of or mriti h on pipeline medium. Operat on manners are in general of manual, and pneunatic or electric actuators are available. Based on design structures, the valves get drvided into three pieces, two pieces, and one piece types.

GEP - Butterfly Valve

Design and Manufacture comply to: AP1609,FN5S81,MSSSP&7. Inspection and Test comply to: API 598. EFace to face dimension comply to: BS515S. Flanges comply to: API 605. Pressure temperature grade comply to: ANSI F&.34.