- Home

- Companies

- G.E.P. Valves s.a.s.

- Products

- GEP - Trunnion Ball Valves

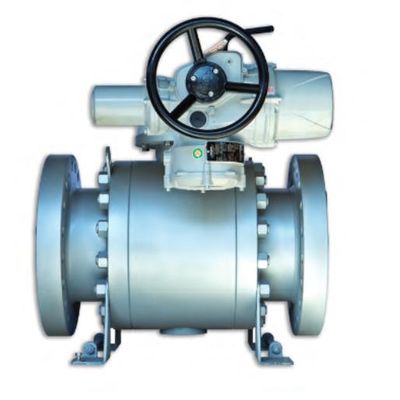

GEP - Trunnion Ball Valves

Design and Manufacture: API 60, ASME B16.34.{BS5351), API 608, MSS-SP-72. Face to face Dimension: ASMEB16.10.AP16D. Flange Connection Dimension: ASME B16.5, NPS>26`) PER as ASME B16.47. BW Connection Dimension: ASME B16.25. Test and Inspection: API 598, API 60. Fire-safe Design: API 607/6FA. Anti-statk Design & anti Blow-out Stem.

Urgent grease injection device

According to customers` requirement, the trunnion ball valves supplied by G.E.P. Valves company are provided with devices for urgent grease injection, which are on both the stem and seat for the trunnion ball valves of DN > 150mm (NPS6), and in the body cavity for the valve of DN <125mm. When the O ring of stem or the body seat ring is damaged due to accident, the medium leakage between body and stem can be prevented by injecting the sealing grease through the device.

Double-block and bleed functions

In general, G.E.P Valves trunnion ball valve features the front ball sealing design structure. Each seat of the ball valve can separately cut off the medium at both inlet and outlet of the valve to realize doubJe-Wodc functions. When the ball valve is dosed, body cavity and two of the body ends can be blocked with each other even if both the inlet and outlet are under pressure, when the medium left in the body cavity might be bled through the relief valve.

Self-relief in the body cavity

As the liquid medium left in the body cavity gasifies due to increased temperature, the pressure in the body cavity becomes abnormally higher whon the medium itself in the cavity would propel the seat and self-relieves the pressure to ensure the safety of valve.

Blow-out proof stem

Blow-out proof structure is provided with for the stem, which is positioned by the up-end cap and screw, being guaranteed not to be blown out by the medium even if at abnor mal risen pressure in the cavity.