GIG Karasek GmbH products

Thin Film / Short Path Technology

GIG Karasek - Thin Film Evaporator

Special solutions for demanding tasks: The Thin Film Evaporator made of high quality materials provides the highest performance and allows even to separate sensitive products in small quantities. Depending on the manufacturing and product requirements, we develop for each of our clients tailor-made distillation modules. Their heartpiece – individually selected evaporators with perfectly matching rotor types.

GIG Karasek - Short Path Evaporator

Powerpackage for universal fields of application; The GIG Karasek Short Path Evaporator offers a particularly wide range of services in spare evaporation technology for delicate fabrics. The spectrum of special apparatus reaches from high evaporation to fine vacuum distillation at pressures up to 0.001 mbar. It is based on the same powerful principle as that of the Thin Film Evaporator. The subtle difference lies in the built-in capacitor of Short Path Evaporator, which leads to an even shorter and more gentle evaporation process and greatly minimizes the path of the vapors to the condenser.

Evaporation Technology

GIG Karasek - Multi-Stage Evaporation Plants

In multi-stage evaporation, the vapor from the liquid medium is used to heat the subsequent stages. As a result, the use of primary steam can be significantly reduced and the plant can be operated cost-effectively and energy-efficiently.

GIG Karasek - Mechanical Vapour Recompression

In the mechanical vapor recompression, the vapors are compressed by an electrically operated compressor and used again to heat the evaporator. Depending on the application (boiling point increase, heat transfer), one- or two-stage turbo-ventilators or turbo-compressors are used as heat pumps.

Falling Film Technology

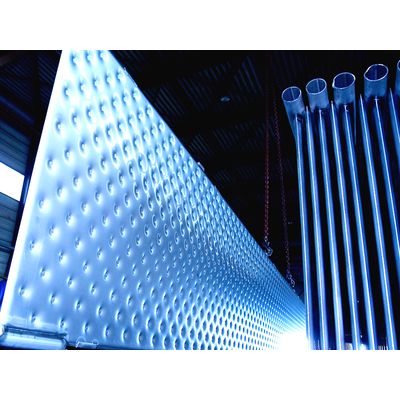

GIG Karasek - Plate Falling Film Evaporator

Ideal for capacity expansion of existing plants or bundle exchange. Plate film evaporators are one of our core competences and are characterized by excellent quality, best energy values, highest condensate qualities and above-average long operating times. Years of design experience, automation of processes and welding know-how enable plate falling film evaporators to be globally competitive.

GIG Karasek - Tube Falling Film Evaporator

Tube falling film evaporators are used in many standard applications and smaller evaporation capacities than plate falling film evaporators. Especially the droplet separation and the cleaning of the apparatus play an essential role. We bring in our years of experience and specialized knowledge of the most individual challenges in the design and manufacture of this type of evaporator.

Others

GIG Karasek - Rectification (Thermal Separation Process)

Rectification is a thermal separation process in which the more volatile components of a mixture are recovered and concentrated. The supply of thermal energy vaporizes the more volatile components and the ascending vapor phase comes into contact with descending liquid (reflux of volatile components). Part of the condensate is discharged as top product. The reflux contact normally occurs in trays or packages installed in a column. Increasing the number of rectification steps raises the concentration of the most volatile component. This means that the concentration of the low-volatile component is increased by forwarding of the top product of the first rectification column into a second column.