Global Technology Systems (GTS) products

Solids Flow

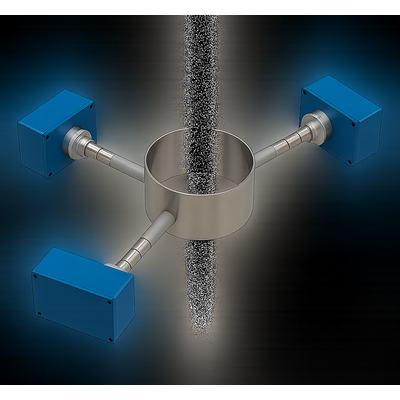

GTS MultiFLOW - Mass Flowmeter for Solids In Large Pipes Or Chutes

Triple Sensor Input. Free fall or Dilute-phase pneumatic conveying. True Mass Flow Output. For pneumatic conveying and freefall processes (typically 1 to 400 tph). Easy installation and start up procedures for calibration. Integral solids flow measurement for all types of powders, granules, flakes, chips, etc.. Install on pipe diameters greater than 8 inches (chutes and ducts need to be reviewed). Long-term stable, reliable, and redundant. Sensor supply for connections up to 1000 m. Galvanically separated RS485-Interface for PLC-Connection. Analog 4-20 mA output, RS485 and alarm relay.

GTS MoistIQ - Continuous Inline Moisture Measurement for Bulk Solids

Real-time, inline moisture measurement (up to ±0.1% accuracy depending on material). Measures and averages up to 8” into the material for total moisture – not just the surface. Ideal for screw feeders, bins, conveyor belts. Maintenance-free, ceramic/Teflon/POM sensor surfaces. ATEX Zone 20/0 options available for Ex. User-friendly Windows software and intuitive calibration. Up to 24 calibration recipes can be stored, 16 of which can be selected via digital input. Long-term data logging, alarms, and Modbus integration. No lab delays – act instantly on moisture changes.

Flow | No Flow

GTS FLOWguard - Model 310 - Flow Monitor for Solids In Free Fall, Sliding Or Pneumatic Systems

Low cost FLOW-NO FLOW switch for solids . Relay Output for Flow or No Flow Condition. Detection of moving material only – no influence from deposits or rotating objects >6″ away. Long-term stable, reliable, robust and repeatable. Stainless Steel housing. General Purpose IP67.

GTS FLOWguard - Model K - Flow Trend Measurement of Powders In Pipes

The FLOWguard K series are used to monitor solids flow in small hoses and pipelines, such as in pneumatic conveyor systems or free-fall sections from a few g/hr to many t/hr. Malfunctions in conveying systems or process upsets for powder, granules, pellets and other bulk materials are detected at an early stage and thus avoided. This helps prevent equipment failures such as clogged lines, wasted material, idling, or other serious problems. Ideal for ensuring additive feed lines are running smoothly. The measuring principle is based on the detection of electrical charges, which naturally sit on the particles of the solid flow, for example due to friction on the wall. Dormant solids are not detected. The device cannot be used with products that form an electrically conductive layer on the inner wall due to abrasion or caking.

Solids Velocity

GTS Dvel - Velocity Measurement for Bulk Solids

Extremely Accurate Velocity Measurement for Bulk Solids. Measurement of Dust, powder or granules in pneumatic conveying and gravity pipes.

GTS SpeedFlow - Speed Measurement System for Solids

Usable in free fall and in pneumatics. Continuous speed measurement of solids (powder, granules, dust) in metal pipes. Measurement directly in the conveying stream / entrained flow. Measurement is completely independent of material. Simple retrofitting using a welding socket.

Point Level

GTS Point-Guard - Model L - Level Detection of Bulk Solids Microwave Barrier

The measurement system Point-Guard L is a microwave barrier and consists of a transmitter and a receiver unit. It is used for level monitoring or level detection of bulk material e.g. in silos, pipelines, chutes, containers, feeding- / receiving vessels and hoppers.

GTS ProGap - Fill Level and Limit Level Detection

Microwave barrier for contactless detection of dry bulk solids in containers, in pipes or in shafts. Simple and uncomplicated retrofitting. Reliable fill level and limit level detection. Detection through all non-conductive walls. With process adapter up to 220 °C and 20 bar pressure possible. With ceramic mounting up to 1,000 °C possible. Absolutely insensitive to material cakings. Can be used up to a profile of 18 m (larger profiles on request). Compact device – no separate electronics. Signalling through relay switching. Can also be supplied in short housing with separate electronics.

GTS ProGap - Model S - Level Detection System

Microwave barrier for the contactless detection of dry bulk solids in containers, piping or shafts. Absolute insensitive to material caking. Can be used up to a profile of 18 m (larger profiles on request). Can be used with adapter up to 220 °C and 20 bar. With ceramic mounting, usable up to 1,000 °C. Usable in dust EX-zones. Signalling through relay switching. Detection through non-conductive walls. Extra short sensor with separate analysis unit. Now with Filling-Signal-Suppression.

Moisture Measurement

GTS - Model MSP - Moisture Sensing Probe

Online Moisture Measurement for Solids. Continuous humidity measurement in dry bulk solids. Contact measurement / passive / No moving parts (optional Non-contact IR Models available). Moisture ranges 0 … 85%. Output Signal: 0/4 – 20mA or 0 – 10V. Compact design, Stainless Steel housing, Ceramic face for high abrasion resistance. Accuracy: 0.1% … 0.5% depending on installation, calibration and process conditions. General Purpose or EX Certified. Reliable, long-term stable, maintenance-free. FMP-2 touch-screen transmitter for higher accuracy with multiple calibration points. High temperature version up to 190°C.