- Home

- Companies

- Global Technology Systems (GTS)

- Products

- GTS MultiFLOW - Mass Flowmeter for ...

GTS MultiFLOW - Mass Flowmeter for Solids In Large Pipes Or Chutes

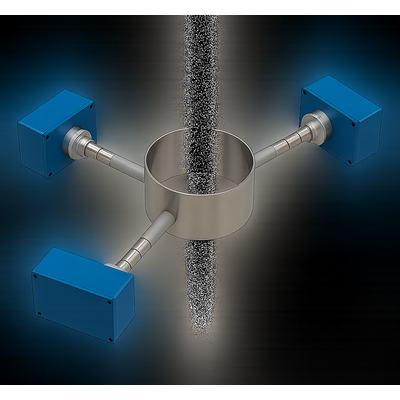

Triple Sensor Input. Free fall or Dilute-phase pneumatic conveying. True Mass Flow Output. For pneumatic conveying and freefall processes (typically 1 to 400 tph). Easy installation and start up procedures for calibration. Integral solids flow measurement for all types of powders, granules, flakes, chips, etc.. Install on pipe diameters greater than 8 inches (chutes and ducts need to be reviewed). Long-term stable, reliable, and redundant. Sensor supply for connections up to 1000 m. Galvanically separated RS485-Interface for PLC-Connection. Analog 4-20 mA output, RS485 and alarm relay.

MF METER (Solids Flow) uses the principle of the Doppler effect.

A microwave signal is emitted, thereby generating an electromagnetic field inside the pipes. The particles passing in movement in this field generate a signal that varies in amplitude and frequency. The rate of flow is computed from a mathematical analysis combined with a calibration (with real measurements).

The Smart HMI Controller combines the raw signals of all 3 sensors and produces an accurate overall flow measurement usually within +/- 1-3% FS. This intelligent system compensates for material randomly flowing at different concentrations within the pipe diameter.

Why Use Three MF METERs?

- Eliminates Flow Profile Bias: Product rarely flows uniformly in wide pipes or chutes. Averaging three independent measurements eliminates errors caused by asymmetrical flow.

- Redundant Measurement: Ensures continued operation if one sensor fails.

- Improved Accuracy: Captures localized variations, delivering a reliable overall mass flow value.

Beyond the working principle, the technology developed for MultiFLOW METER allows the equipment to compensate for variations in:

- Concentration

- Speed of particles

- Granulometrics

- Temperature

- Buildup

FOR BETTER PRECISION.

FOR BETTER REPEATABILITY.

FOR BETTER STABILITY OVER TIME.

Contactless measurement

Very easy-to-use device

No maintenance

No remote electronic handling

SENSOR MOUNTING PROCEDURE :

- Position the circlip on the waveguide regarding depth of the bushing + valve +

bracket + thickness of the pipe.

For optimal operation, the sensor head should be at least flush with the inside of the

pipe or slightly inside.

Use a depth gauge to determine the exact depth - Unscrew the headless screws of the blue holder bracket.

- If you have a valve, open the valve to allow the passage of the waveguide.

- Insert the waveguide sensor proper depth.

- Secure the sensor with the screws.