H-Screening products

Solids Control Equipment

Drilling Mud Shale Shaker

ZS11 Series Shale Shakers is configured with four, three or two screen panels. ZS113 ZS114 shakers’ screens are interchangeable with Mongoose screen replacement (1165x585mm) which allows users to easily source the screen panels locally or aboard. This can reduce rig down time due to the lack or not-prompt supply of screen panels.

Mud Cleaner

Mud cleaner is a combination of desander, desilter and dewatering shale shaker. It is a compact design, small footprint, three in one unit widely accepted by nowadays drilling contractors. It is often installed after the shale shakers where the sand trap drilling mud feeds into the desanders and desiters respectively, the underflow of hydrocyclones loads onto the dewatering screens for recycling the usefully drilling fluids back to the mud system. The drilled cuttings above the screens are therefore dried which lowers drilling cuttings disposal cost.

Polyurethane Hydrocyclone Units

The specially designed drilling mud hydrocyclone units are primarily used for removal of sand-size and silt-size particles from returned drilling fluids. Abrasion resistance polyurethane hydrocyclones are applied to the unit. The unit can be stonealone for use or assembled above our shale shaker through pre-designed connectors. The number of desander and desilter cones is customizable according to the real conditions.

Decanter Centrifuge

Decanter centrifuge is a horizontal solid bowl centrifuge with scroll conveyor inside. Our purpose designed drilling mud decanter centrifuge comes with high wear-resisting and excellent corrosion-resistant performance. They are commonly used as oilfield solids control equipment for barite recovery and ultra fine solids removal. In closed loop mud system, the decanter performs as an efficient sludge dewatering centrifuge following chemical flocculation process with automatic dosing system. VFD decanter centrifuges are often chosen to reclaim water and/or oil from drill cuttings in drilling waste management system.

Drilling Mud Agitator

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole. The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration. Both horizontal / vertical drilling mud agitator available for option.

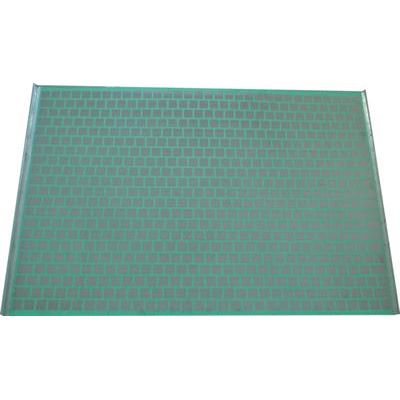

Shale Shaker Screen - PMD / Flat Panel

Flat Screen Replacement

The 48×30 / 2000 FLC Screen Replacement is available in both flat screen (PWP) and pyramid screen (PMD).

Flat Screen Panel Replacement

The 500 FLC Screen is available in both flat screen (PWP) and pyramid screen (PMD).

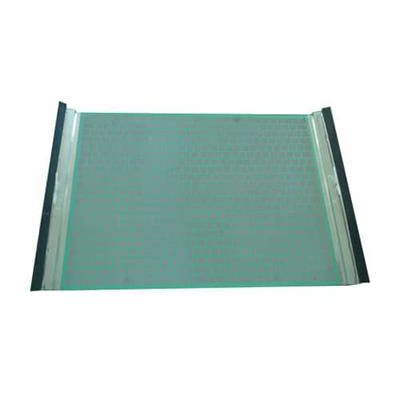

Shale Shaker Screen - MI-Swaco Screen

Mongoose Shaker Screen

Mongoose Shale Shaker Screen comes with either steel frame or composite material frame screen. H Screening produces both type of screens. We highly recommend the composite material frame screen which enjoys a longer service and reduces the downtime during operation.

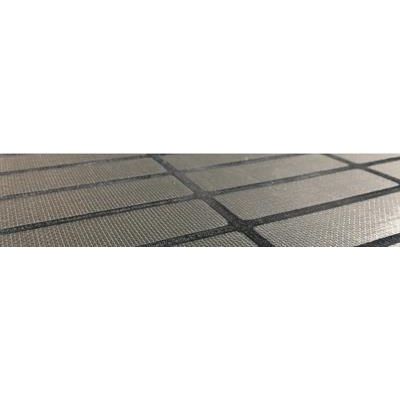

Shaker Screen

We design and manufacture MI Swaco replacement screen. MI Swaco ALS shaker screen is hook type screen. The tension is applied through edge treatments on the woven wire cloth screen panel commonly referred to as “hooks” or “hook strips”. Proper screen tension is crucial for effective screening and longer screen life. Banded Hook edges increase strength (prevent flattening) and eliminate mesh pull-out on fine wire mesh or high tension screens.

Shaker Screen

BEM-600 is a M-I Swaco shaker model. The BEM-600 shaker screen is pre-tensioned steel frame screens and is fitted into the shaker by wedges.