Hangzhou Hengyi Filter Co., Ltd. products

Sintered Mesh

Sintered Metal Porous Material

Sintered mesh is a rigid structured composite consisting of multi-layers of metal woven mesh, manufactured from a special lamination design and undergoing a combination of processes such as rolling and vacuum sintering.

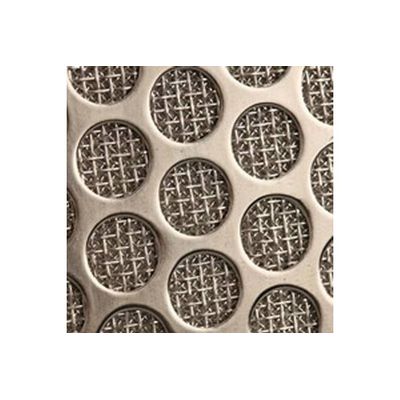

5-Layers Sintered Stainless Steel Mesh

5-Layers sintered stainless steel mesh is our standard sintered mesh structure. A single layer of fine woven wire mesh is placed between two layers of coarser square woven meshes, which is then added to two layers of a strong Dutch woven wire mesh and sintered together to form a strong plate. The single layer of fine woven wire mesh acts as the filtration layer, and can be customized to meet a particular filtration rating, ranging from 5 micron to 300 microns. It can then be cut and fabricated into various discs, tubes, filter cartridges, and flat panels.

Multi-Layer Sintered Stainless Steel Mesh

This type of Sintered Wire Mesh Laminate is made by sintering multiple layers of plain weaven square woven wire mesh together. Because of the large open area percentages of the square woven wire mesh layers,this type of sintered wire mesh laminate has good permeability and low resistance to flow.It can be desigan with any number and combination of square plain weaven wire mesh layers to achieve particular flow and filtration characteristics.This type sintered wire mesh is usedful for plolymer production,as well as variety of fluid and air filtration applications.

Perforated Sintered Stainless Steel Mesh

This type of Sintered Wire Mesh Laminate is made by taking several layers of woven wire mesh and sintered them to a layer of perforated metal.The woven wire mesh layers consist of a filter layer,a protective layer and possibly a buffer layer between the fine mesh layer and the perforated plate.The perforated plate is then added as the base and the entire structure is sintered together to form a very strong yet tractable plate.Due to the support of the perforated plate,this type of sintered wire mesh laminate has a high resistance to pressure and high mechanical strength.It is suitable for a variety of applications which require fine filtration,but also the need to protect and preserve the filtration layer.One example of an application is in oil wells,where fine particles need to filtered under extremely high pressure conditions.

Wire Mesh

Multi-Layer Sintered Stainless Steel Mesh

This type of Sintered Wire Mesh Laminate is made by sintering multiple layers of plain weaven square woven wire mesh together. Because of the large open area percentages of the square woven wire mesh layers,this type of sintered wire mesh laminate has good permeability and low resistance to flow.It can be desigan with any number and combination of square plain weaven wire mesh layers to achieve particular flow and filtration characteristics.This type sintered wire mesh is usedful for plolymer production,as well as variety of fluid and air filtration applications.

Titanium Mesh

Material : Titanium wire. Application : Applied to acid, alkali resistance, high temperature environment, marine environment, as well as electrode net. Grade : 8 mesh and -150 mesh.

Brass Mesh

Material : Brass wire, phosphor bronze (tin bronze wire), copper wire. Application : Screening a variety of granules, powder, porcelain clay, glass, chinaware printing, filter liquid, gas, etc.. Grade : Square mesh of 40 mesh and -200 mesh / 25.4mm.

Filter Elements

Leaf Filter Elements

Media : 316L stainless steel Sintered mesh. Advantage : Strength and durability. Wide filtration range and high flow rates. Adjustable filtration range. Reusable.