Harber Coatings Inc. products

Harber - Electroless Nickel Coating (ENC) or Electroless Nickel Plating (ENP)

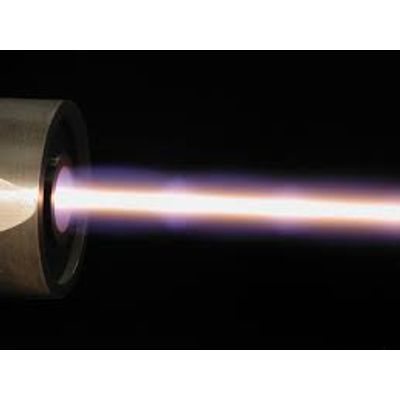

Harber - Supersonic Arc Metal Spray

Supersonic Arc Metal Spray is a protective coating that is especially successful to prevent storage tank corrosion. Today, epoxy coatings are widely used for metal part and storage tanks but there are often issues such as ageing, permeasion, peeling, etc.

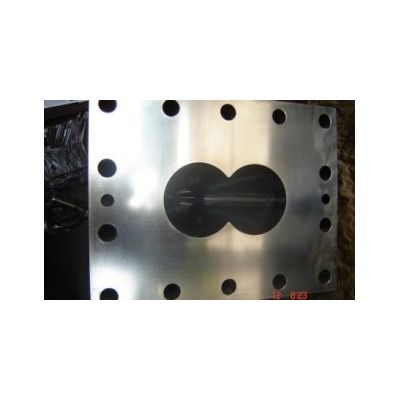

Harber - Laser Assisted Nano Fusion Technology

Traditional plasma overlay destroys a big portion of the designed mechanical properties of an overlay, due to the very high temperature of the process. Harber Coatings` Laser Assisted Nano Fusion process does an overlay at extra low temperatures, therefore there is no stress issue caused by the process, no damage to the substrate, and the designed mechanical properties, including nano properties (when nano materials are used).

InnoGUARD™ Flakeless ENC

Harber - Model 300 - Electroless Nickel Coating

InnoGUARD 300 is an economical high phosphorous-nickel formula designed for high acid corrosion resistance. The amorphous characteristics of this coating provides excellent corrosion resistance and up to 50 Rc hardness for good abrasion resistance.

InnoGUARD - Model 300H - Flakeless Electroless Nickel Coating (ENC)

The InnoGUARD 300H is a heat treated and hardened formula designed to achieve a crystalline structure. Compared with hard-chrome, this coating has superior wear and much higher corrosion resistance (to prevent substrate corrosion). This coating is optimal for significant wear-abrasion applications, including oilfield downhole tools, achieving Vickers Hardness ~ 900HV.

Harber InnoGUARD™ - Model 300M - Coating

Harber’s InnoGUARD™ 300M formula was developed specifically for marine and off-shore applications. This performance coating is excellent for corrosive environments with severe temperature changes and serious abrasion factors Our unique processing technologies have made the 300M a very successful coating in harsh environments, achieving a Vickers Hardness of up to 850HV (greater than 68 Rc).