Harrington Process Solutions products

Pipe & Fittings

PVC Pipe

PVC is the most commonly used plastic material for manufacturing plastic pipe. It has a relatively high tensile strength and modulus of elasticity and, therefore, is stronger and more rigid than most other thermoplastics. Joining methods are by solvent cementing, threading (Schedule 80 only) or flanging. PVC has been used successfully in such areas as chemical processing, industrial plating, chilled water distribution, salt water, chemical drainage, and irrigation systems. Pressure ratings given are for solvent-cemented systems. When adding valves, flanges or other compo¬nents, the system must be derated to the rating of the lowest component: threaded fittings are rated at 50% of solvent cement systems; flanged fittings are rated at 150 psi; union fittings are rated at 235 psi. See manufacturers` recommendations for other ratings.

Large Diameter PVC Pipe

Maximum recommended fluid velocity is 5` per second, Manufacturer`s pressure ratings must be strictly followed; many fabricated fittings do not carry the same pressure rating as pipe, Other sizes and configurations available up to 30` diameter, Reduced pressure-rated fittings are available in most configurations, All PVC Schedule 80 pipe shall be manufactured from a Type 1, Grade 1 PVC compound with a Cell Classification of 12454 per ASTM D1784, Large diameter solvent cement assembly requires extra heavy duty slow setting cement and primer, Special tools are available for proper assembly of large diameter solvent cemented piping systems.

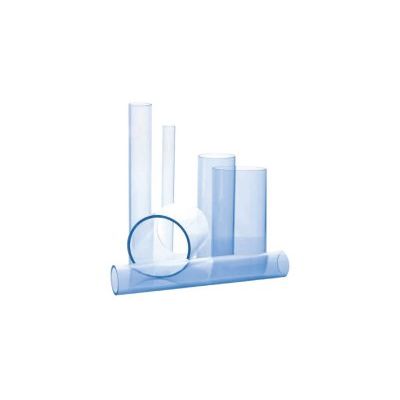

Clear PVC Pipe

PVC clear Schedule 40 or Schedule 80 piping provides optimum clarity for critical visual monitoring of processes fluids. Joined using standard solvent cement welding with clear cement, clear systems provide the many benefits of regular PVC, such as excellent corrosion resistance, smooth interior walls, non-contaminating, non-conductive, light weight, good pressure handling capacity, superior impact strength and does not support bacterial growth.

IPEX - Clear-Guard Clear PVC Pipe

With IPEX`s new high pressure clear PVC pipe you can specify Schedule 40 clear pipe for applications where previously only Schedule 80 clear pipe would suffice. Our high pressure formulation, with a long-term hydrostatic design basis of 3,150 psi allows for better clarity and more versatility for various applications. IPEX Clear-Guard Clear PVC pipe is produced from a rigid, virgin Polyvinyl Chloride (PVC) compound with a Cell Classification of 15334 per ASTM D1784. This material also enables Clear-Guard Clear PVC piping to carry a maximum service temperature of 140oF when appropriate temperature/pressure derating factors are applied.

GF Harvel - EnviroKing UV Resistant Clear PVC Pipe

ThinWall™ and standard Schedule 40 dimensions, Joined utilizing simple solvent-welded joining techniques, Manufactured to IPS dimensions Fully compatible with standard PVC pipe, fittings, and valves, Non-conductive, Lower overall installed cost than glass, acrylic, or other transparent alternatives.

CPVC Pipe

CPVC has similar, but generally better, chemical resistance and physical properties than PVC. Joining methods are by solvent cementing, threading (Schedule 80 only) or flanging. CPVC has been used successfully for process piping, for hot corrosive liquids, and in hot and cold water distribution. Pressure ratings given are for solvent cemented systems. When adding valves, flanges or other components, the system must be derated to the rating of the lowest component: threaded ratings are 50% of solvent-cement systems; flange fittings are 150 psi. See manufacturer`s recommendations for other fitting and component ratings.

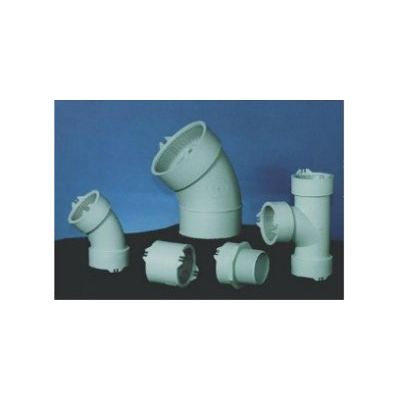

Double Containment

IPEX Guardian - Double Containment

Certain environments demand fail-safe systems. No leaks. No risk. The professionals at IPEX understand the complexity of design and installation for demanding double containment applications. And, unlike other manufacturers of double containment systems, our specialists are part of a division of IPEX dedicated solely to the design, production and installation of state-of-the-art double attainment systems. With more than 20 years of experience and success, we are the proven experts. The IPEX family of double containment systems includes: Guardian PVC and CPVC pressure and drainage systems, Encase PolyPro drainage systems, CustomGuard FRP and metal pressure systems, and Centra-Guard leak detection systems.

Acid Waste and Drain

IPEX Enfield Fusion

The Enfield Socket Fusion System consists of flame-retardant polypropylene pipe, fittings, traps and accessories necessary for the drainage of laboratory and industrial waste chemicals. It can also be used in conjunction with Labline and Plenumline Mechanical Joint Systems and the Encase Double Containment System.

Valves & Actuation

Model Type 21 - Ball Valves

Features: True Union design for easier installation or repairs without expanding pipe system. Blocked in both directions allowing valve union disassembly from either side under full pressure. Type 21 Ball Valves carry a two-year guarantee. Materials: PVC, CPVC, polypropylene, PVDF with EPDM, or FKM elastomer seals. Pressure rated to 230 psi (PVC, CPVC, PVDF), full vacuum rated. Double 0-ring stem seals and blow out proof stem design for added leak protection. Integrally molded ISO mounting pad for both manual accessory and actuation assembly. Integrally molded base pad to surface or panel mount valves securely. PTFE seats with elastomeric backing cushions ensure bubble-tight shut off and low cycling torque while compensating for wear. Built-in spanner wrench on handle for valve repair. Socket and threaded end connectors included with all ½-2” PVC and CPVC valves,. ½-1”CPVC threaded end connectors are stainless steel reinforced for high temperature performance.

Instrumentation

Model Series 2536 - Rotor-X Low Flow Sensors

Features: Ideal for measuring flow in piping systems with velocities as low as 0.3ft/s. Combines Hall Effect sensing with advantage of insertion paddlewheel technology. Manufactured under ISO 9001/14001. Sensor materials:. Body: Polypropylene or PVDF. Shaft: Titanium or Hastelloy C. Rotor: PVDF. 0-rings: FKM. Requires external power 6-24VDC regulated. Standard cable length is 25"; 1,000" maximum This sensor can be used with:. 5500 flow monitor 5600 batch controller 8550 transmitter 8900 multiparameter controller.