Harsco Metals & Minerals products

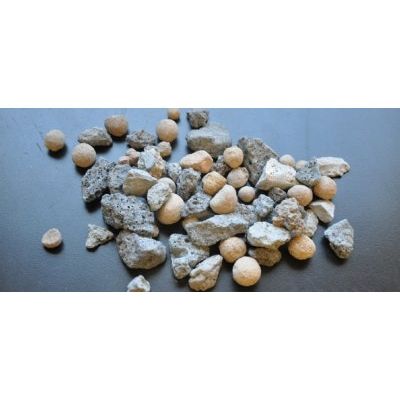

Metallurgical Additives

Ladle Desulfurizers

Custom-designed, lime-based Desulfurizers for efficient steel refining in the ladle are engineered to provide cost effective desulfurization during and after furnace tapping. This is achieved by the immediate production of a molten slag with an increased desulfurization potential. The rapid fluidization of the entire ladle slag increases the absorption of sulfur and non-metallic inclusions throughout each stage of ladle refining. These custom-designed products are available with specified levels of metallic aluminum or silicon to improve the efficiency of the desulfurizing process. This allows the specified sulfur levels to be reached within the time required. Premelted MgO is also provided to generate rapid and ongoing refractory protection.

Slag Conditioners

Our aluminum and silicon-based Ladle Slag Conditioners/Deoxidizers are designed to quickly assimilate into the entire ladle slag volume. This facilitates a complete reaction with the carryover furnace slag to effectively reduce the FeO and MnO contents of the slag in the ladle. The result is a more effective slag deoxidation process, which improves alloy recoveries, increases desulfurization efficiency and provides protection to the ladle slagline. These custom-designed products are available with specific levels of metallic aluminum or silicon to lower the oxidation potential of the ladle slag. This decreases alloy fade and thereby minimizes caster clogging and quality downgrades. The final desired outcome is a cost effective and efficient ladle refining process.

Calcium Aluminate

Our calcium aluminates are engineered to be a cost effective approach to fluorspar-free ladle slag fluxing. As many aluminum killed steel shops are restricted in the use of fluorspar, calcium aluminate consumption has increased as a means of fluidizing CaO in a quick and effective manner. Our extensive line of calcium aluminate products offers a wide range of capabilities to balance ladle slag chemistries while providing the basicity and fluidity required for effective steel refining in the ladle. Calcium aluminates also help to dilute the overall FeO and MnO levels in the carryover slag.

Synthetic Slag

We deliver effective ladle metallurgy treatment through our line of calcium aluminate, calcium silicate and calcium fluoride-based Synthetic Slag products. Each are chemically engineered to rapidly form a highly basic and fluid slag that will absorb impurities such as sulfur as well as the products of steel deoxidation. This ladle refining treatment helps create a steel product with low inclusion levels and within specification to maximize castability, productivity and product quality. These Synthetic Slags are produced with an engineered balance of premelted fluxes to increase the lime/slag melting rate and control the final slag fluidity. They are also custom formulated with supplemental magnesia to extend ladle slagline refractory life.

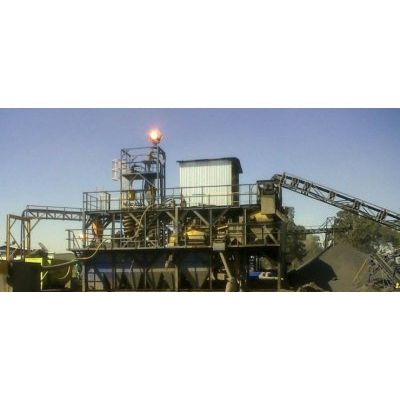

Resource Recovery

Jigging Technology

Current ferroalloys production worldwide amounts to 30million tons per annum, mainly for use as a raw material in the steel and stainless steel industries. Chrome, manganese and silicon ferroalloys account for much of the production, though others include Ferromolybdenum, Ferronickel, Ferromolybdenum, Ferrotitanium and Ferrovanadium. The major ferroalloy-producing countries are China, South Africa, Russia, Kazakhstan and Ukraine. China`s leading position is due to its dominance in steel production, rather than because of the abundant presence of native ore reserves.