- Home

- Companies

- Hein, Lehmann GmbH

- Products

Hein, Lehmann GmbH products

Screening Machines

Liwell - Screening Machines

LIWELL screening machines have been in operation for decades and are the guarantor for optimal technology in classing feed materials which are difficult to screen. The special construction generates accelerations on the screen panel, unequalled up to now, of approx. 50 g - where the machine structure is subject to small forces only, of approx. 3 g. Different types and designs of the machines and screen mats provide an optimal solution for every case of application. The basic principle of the trampoline-like movement of polyurethane screen mats, from loose to tension to strongly stretched condition, is used in all types.

Liwell - Stationary Mobile Screening Machines

The mainly stationary machine construction is completed by mobile variants:

Liwell - Screening Machines

The LIWELL screening machines Type KT for fine screening of coarse feeding materials: Through a symbiosis of circular vibration and flip-flow screening, it is possible to classify coarse bulk materials with the LIWELL KT type. The upper deck is operated as a circular vibratory unit and serves as a protection deck. On the lower deck, the difficult to screen fine separation is executed by means of flip-flow movement. dxAccording to requirement, the protection deck (upper deck) can be equipped with all types of screen panels and exchange systems. On the lower deck, the well-proven LIWELL screen mats make sure an effective fine screening.

Liwell - Screening Machines

The best seller of the LIWELL® screening machines – Type LF - is characterized by its unique properties:

Hein Lehmann - Circular Vibration Screening Machines

Conventional HEIN, LEHMANN screening machines offer the ideal solution for all standard applications. The bolted/welded construction with unbalanced shaft or unbalanced motor drive keeps the maintenance expenses low and provides a long service life.

Hein-Lehmann - Linear Vibration Screening Machines

Conventional HEIN, LEHMANN screening machines offer the ideal solution for all standard applications. The bolted/welded construction with unbalanced shaft or unbalanced motor drive keeps the maintenance expenses low and provides a long service life.

Screen for Processing Raw Materials

Hein-Lehmann - Wire Cloths

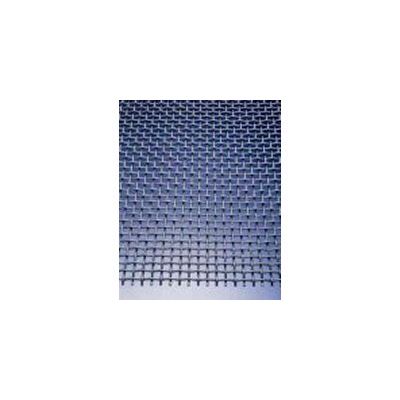

HL wire cloths in square and long mesh finish. HL wire cloths in square and long mesh finish are crimped and mechanically woven under pre-stressing to a tight compound. This gives the cloth a high vibration strength and long service life.

Hole Sheet

Conidur - Fine Hole Sheets

The CONIDUR fine hole sheets have a more triangular-shaped to semi-elliptical opening, compared to the slotted hole sheets. Here you find an overview of the dimensions of the CONIDUR® fine hole sheets. CONIDUR-Feinlochbleche als Anströmboden in einer Fließbett-Anwendung.CONIDUR® fine hole sheets as a distribution deck in a fluidized bed application.

Wedge Wire Screens

Corima - Welded Wedge Wire Screens

Corima welded wedge wire screens consist of sequentially arranged wedge wires which are connected vibration-resistant with cross bars to a firm screen by means a resistance welding. This results in screen openings in form of slots in-between the profiles. Theses slots can be adapted in their width according to application.

Wire Belts

Hein-Lehmann - Spiral Wire Link Belts

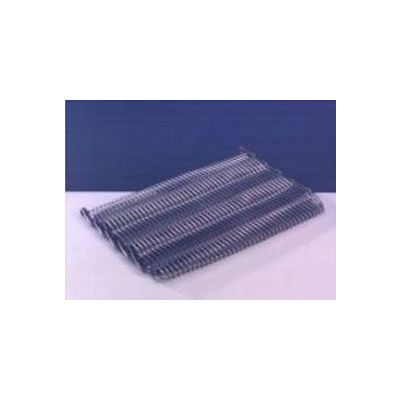

The spirals of these belts are alternately wound clockwise and anti-clockwise. A straight belt motion is achieved by that to a large extent. Through the tightly wound spirals, there results a large total cross section. Therefore a high tensile load is possible. In the case of belts which are driven through chains, this leads to possible small roll diameters and to a constrained leading of the belt achieving therewith a saving of space in the conveyor machine.