100 products found

Henan Doing Machinery Equipment Co., Ltd. products

Doing - Model DY 6t 8t 10t - Waste tyre pyrolysis to oil machine

Waste tyre pyrolysis to oil machine working principle:

1. Use auto-feeder to feed the waste tyres into reactor automatically, seal the feeding inlet door tightly.

2. Heat the reactor by burning the following fuel material: coal, wood, natural gas, or fuel oil in the combustion system. The reactor will be heated slowly, when the temperature reaches around 250 degree Celsius, the oil gas will be formed.

3. After processed by DOING waste tyre pyrolysis to oil machine, the oil gas will go to the cooling system to be liquefied. The gas which cannot be liquefied under normal pressure will be designed to go back to combustion system through safety device instead of the fuel material to burn the reactor, which is environmental friendly and can save you much energy.

4. After finishing oil collecting, the temperature of reactor will be down, while, carbon black can be discharged automatically at the same time.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Doing - Model DY 6t 8t 10t - Waste plastic pyrolysis machine

The whole waste plastic pyrolysis machine composite by 13 parts, those are reactor ,driving device ,vertical catalytic chamber, vertical condenser, oil and water separator, horizontal condenser ,heavy oil tank ,light oil tank , anti-back fire device, vacuum system , dedusting device, draft fan, chimney.

Reactor is one of the most important parts. The material and welding technology of reactor will have a direct impact on safety and durable life. In order to guarantee the quality of reactor, we use auto welder .The welding seam will get X-ray detection and heating treatment.

Condensers adopt water cooling way and the inner cooling tube are made of seamless steel pipe ,the diameter is 48mm.the heat exchanging area is about 13 square meter ,the total heat exchanging area is 40 square meter to get the best temperature for oil gas liquefied.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

www.wastetireoil.com

www.doingg

Doing - Model DY 6t 8t 10t - Used of plastic waste recycling machine

Nowadays, many people advocate the “Green” living, which is approved many people. So it is better to shred, melt and repurpose all these plastic materials instead of throwing away the waste plastic to pollute the environment.

Therefore,Doing makes great efforts to develop and manufacture the used of plastic waste recycling machine, which is very popular after it comes into being. The used of plastic waste recycling machine is a great recycling machine which is can be widely applied to large-scale, large-volume recycling of post-consumer, post-commercial, and post-industrial plastic scrap. The Used of plastic waste recycling machine is mainly used to reprocess plastic and make the material reusable for another product.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

www.wastetireoil.com

www.china-doing.com

Waste engine oil to diesel machine - Model DY 6T 8T 10T - Waste engine oil to diesel machine

Used engine oil refers to engine oil has become black and the viscosity has increased, because of mixing with water, dust, other oils as well as metal powder; it also refers to engine oil has deteriorated and produced organic acid, colloids and asphaltic substances. Recycling of waste engine oil is to removal impurities using settlement, distillation, acid, alkaline as well as filtering.

Used engine oil to diesel machine is also called oil refining machine. It can refining waste oil(waste engine oil,motor oil, tyre oil, plastic oil etc) to clean diesel. The oil recovery yield is about 85% ( according to oil quality)

http://www.wastetireoil.com

Copper wire recycling machine - Model DY 100KG 200KG 500KG - Copper wire recycling machine

Copper wire is valuable because scrap copper wire can be recycled to provide extra value and protect the environment. As the sense of environmental protection becomes popular, there is a great demand of copper recycling machines. Especilaly in some advanced countries such as America, Canada, Australia and Europe. While copper wire recycling machine is just the ideal machine for copper recycling.

http://www.copperwirerecyclingmachinery.com

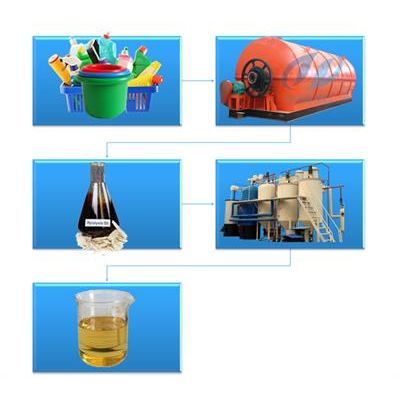

Turning plastic into oil machine - Model DY 6T 8T 10T - Turning plastic into oil machine

The turning plastic into oil machine can convert the plastic waste to energy, such as plastic pyrolysis oil, carbon black and combustible gas. Those products are popular in the market, and they also have a great market value.

1. Plastic oil

The plastic oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline by waste oil distillation plant.

2. Carbon black

The carbon black can be sold to the brick factory as internal combustion or as raw materials of tire, shoe, cable, etc.

http://www.wastetireoil.com

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Tyre pyrolysis oil distillation plant - Model DY 6T 8T 10T - Tyre pyrolysis oil distillation plant

If we want to get diesel fuel ,you should buy two machine ,one maching named tyre pyrolysis plant ,the tyre pyrolysis plant can pyrolysis waste tyre to fuel oil and carbon black ,another machine is waste tyre oil distillation plant .

To convert tyre pyrolysis oil to diesel oil or gasoline, our Tyre pyrolysis oil distillation plant is applied to one kind of advanced technology called distillation or refining.

With this technology, the tyre pyrolysis oil distillation plant can effectively remove the particles, colloidal matter, acid and odour from tyre oil by acid-treatment and filtration. Finally we can get diesel oil with clean and transparent color and qualified smell.

http://www.wastetireoil.com

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Convert waste plastic into diesel - Model DY 6T 8T 10T - Convert waste plastic into diesel

Convert waste plastic into diesel adopts one advanced technology called refining or distillation, which takes advantage of high temperature and heat the plastic oil to working temperature by using fuel oil, gas, coal etc. as fuel materials. Through changing forms of the oil from liquid state to gaseous state and then from gaseous state to liquid state, the distillation technology can successfully remove the particles, colloidal matter, acid and odour from plastic oil by acid-treatment and filtration.

http://www.wastetireoil.com

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Recycling copper wire machine - Model DY 100KG 200KG 500KG - Copper Wire Recycling Machine

Recycling copper wire machine are mainly used to recycle all kinds of waste cable wires, the raw materials will be separated into tiny copper rice and PVC, the applicable range of the wires diameter from 0.3 mm to 20 mm, such as automobile electrical route, car bottom lines, motorcycle electric line, computer case line and communication cable, etc.

http://www.copperwirerecyclingmachinery.com

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Doing - Model DY 6T 8T 10T - Plastic to oil conversion machine

Despite all of the technological advances over the recent years in the reclamation of plastics, there remains a portion of the plastic waste stream that cannot be mechanically recycled due to contamination, lack of markets or the in ability to separate pl astics that can make recovery unfeasible.much of this non - recycled plastic then becomes landfilled.

However, a new generation of conversion technology specifically de signed to manage non - recycled plastics has been developed, and commercial scale facilities that use pyrolysis technology to convert plastics into oil and fuel are being established in Europe and Asia.

Doing produced plastic to oil conversion transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock.

http://www.wastetireoil.com

Mobile/Wechat/Whatsapp:0086-135-2669-2320