- Home

- Companies

- Henan Doing Machinery Equipment Co., ...

- Products

- Doing - Model DY 6T 8T 10T - Plastic ...

Doing - Model DY 6T 8T 10T -Plastic to oil conversion machine

Despite all of the technological advances over the recent years in the reclamation of plastics, there remains a portion of the plastic waste stream that cannot be mechanically recycled due to contamination, lack of markets or the in ability to separate pl astics that can make recovery unfeasible.much of this non - recycled plastic then becomes landfilled. However, a new generation of conversion technology specifically de signed to manage non - recycled plastics has been developed, and commercial scale facilities that use pyrolysis technology to convert plastics into oil and fuel are being established in Europe and Asia. Doing produced plastic to oil conversion transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock. http://www.wastetireoil.com Mobile/Wechat/Whatsapp:0086-135-2669-2320

Plastic to oil conversion machine

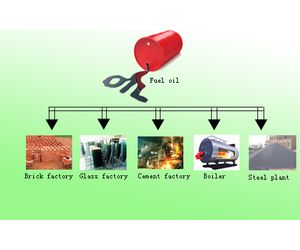

1. Plastic oil

The plastic oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline by waste plastic to diesel plant.

2. Carbon black

The carbon black can be sold to the brick factory as internal combustion or as raw materials of tire, shoe, cable, etc.

3. Combustible gas

The combustiblegas can be recycled to heat the reactor as fuel, which will save energy for the whole conversion of waste plastic into fuel.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com

For more information

Plastic to oil conversion machine

1. Plastic oil

The plastic oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline by waste plastic to diesel plant.

2. Carbon black

The carbon black can be sold to the brick factory as internal combustion or as raw materials of tire, shoe, cable, etc.

3. Combustible gas

The combustiblegas can be recycled to heat the reactor as fuel, which will save energy for the whole conversion of waste plastic into fuel.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com

For more information

Doing produced plastic to oil conversion transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock.

Plastic to oil conversion machine working process

Step -1

Put plastic material into the pyrolysis reactor by mechanical feeding machine or manual, then it is delivered into the store bin with the help of conveyor belt. Then, close the feeding door and open heating system of the machine.

Step – 2

In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3

Cool down the plastic to oil conversion machine after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.

Doing produced plastic to oil conversion transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock.

Plastic to oil conversion machine working process

Step -1

Put plastic material into the pyrolysis reactor by mechanical feeding machine or manual, then it is delivered into the store bin with the help of conveyor belt. Then, close the feeding door and open heating system of the machine.

Step – 2

In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3

Cool down the plastic to oil conversion machine after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.

Doing produced plastic to oil conversion transforming non - recycled plastic into a valuable commodity, and creating a reliable source of alternative energy from an abundant, no - cost feedstock.

Plastic to oil conversion machine working process

Step -1

Put plastic material into the pyrolysis reactor by mechanical feeding machine or manual, then it is delivered into the store bin with the help of conveyor belt. Then, close the feeding door and open heating system of the machine.

Step – 2

In this step, two stages are there in the process. The primary stage: the heat energy needs to start with 100 degree Celsius and ending with 250 degree Celsius. In 100 degree Celsius, the oil gas will release and in 120 degree Celsius the liquid oil will release. The secondary stage: the heat energy needs to change from 250 degree Celsius towards 280 degree Celsius; it is the peak output rate. The oil gas will be collected into the manifold, and the oil as well as the weighty particles are accumulate and dissolved in the center of the manifold and drop into the deep oil container (oil tank). And the lighter oil gas will certainly go up to multifunctional oil condensers to liquefy into oil and keep in the tank.

Step – 3

Cool down the plastic to oil conversion machine after the completion of Step-1 and Step-2. Once the heat reaches about 40 degree Celsius, the carbon black will be discharged automatically.