- Home

- Companies

- Holte Manufacturing

- Products

Holte Manufacturing products

Holte Overburden Systems

Underreamer Guage

The Holte URG (Underreamer Guard) Underreamer has an extendible arm bit and is considered superior to a one-sided UR because three (3) to four (4) arms extend to ream a full gauge (360 degree) hole. The underreamers which swing out on only one side drill slower and not always straight. This bit design was developed at Holte Manufacturing while researching faster ways to drill large diameter holes. Because there is bit surface reaming the full gauge of the hole, this bit wears much better than an eccentric style bit which only reams with about a 50 degree portion of the hole.

Holte Down Hole Drill Bits

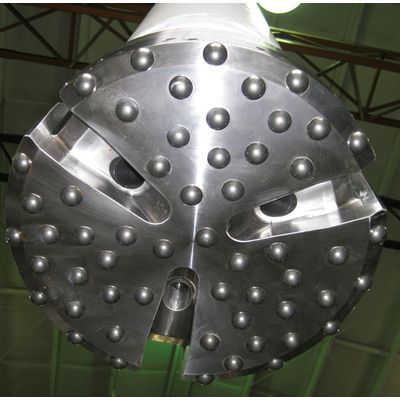

Reverse Circulation Down Hole Drilling Hammer Bits

Holte Reverse Circulation Drilling Hammer Bits Offer Control. As the most experienced reverse circulation manufacturer in the industry we understand bits and the importance of having a durable, effective design leading your tooling down the hole. Our complete line of reverse circulation bits are designed with that in mind.

Holte Down Hole Hammers

Conventional Down Hole Hammer

Holte offers unmatched experience designing and manufacturing conventional down hole hammers and bits. We have keep our same traditional conventional design for years, only to refine it into the efficient and durable design it has become today. Whether you need a DTH Hammer to meet specific specifications for the ground conditions your faced with or you would like our standard design that draws from our past, proven design and heat treatment process, you can rely on Holte`s tooling to work with you and get the job done.

Conventional Drilling Tools - Drill Pipe

Hex Joint Drill Pipe

Holte’s Dual Wall Drill Pipe with Quick Release Hex Head was created by Holte Manufacturing as a solution to the problem of thread binding. This is particularly a problem with large diameter systems using traditional threaded joints due to the higher amount of torque applied to the drill string.

Underreamer Eccentric (URE)

Holte’s Underreamer Eccentric oval shape is designed to have a wide cutting edge on the borehole wall to maximize the underreaming. It is ideal for sensitive overburden conditions. The Holte Percussion Underreamer Eccentric is a two piece tool, a driver section & a bit section. The driver, or splined section fits into a down hole hammer. Available in a Drive Shoe Style or for use with a Casing Driver.

Underreamer Concentric System

The URC Underreamer Concentric is a Ring Bit System is composed of a removable outer ring that attaches to a driver and used with a down hole hammer and casing driver. Its purpose is to underream for casing installation. The ring bit fastens to the driver bit with a press fit which prevents the ring bit from falling off. This system enables a driller to both drill and case simultaneously leaving only the ring in the hole when the job is completed. This ring portion of the bit is larger in diameter than the casing and has a smooth round outer surface.

Conventional Drilling Tools - Underreamers

Holte - Underreamer Gauge

The Holte URG® (Underreamer Gauge) Underreamer has an extendible arm bit (wing bit) and is considered superior to a one-sided UR because three (3) to four (4) arms extend to ream a full gauge (360 degree) hole. The underreamers which swing out on only one side drill slower and not always straight. This bit design was developed at Holte Manufacturing while researching faster ways to drill large diameter holes. Because there is bit surface reaming the full gauge of the hole, this bit wears much better than an eccentric style bit which only reams with about a 50 degree portion of the hole.

Conventional Drilling Tools

Holte - Conventional Down Hole Hammers

Efficient and durable design refined over 45 years. Custom DTH Hammers to meet specific specifications for the ground conditions your faced with or our standard design that draws from our past. Simplest hammer in the drilling industry because it has fewer parts. It has wrench dimples in the barrel, back head, and chuck which make it possible to easily disassemble in the field or in the shop.

Reverse Circulation

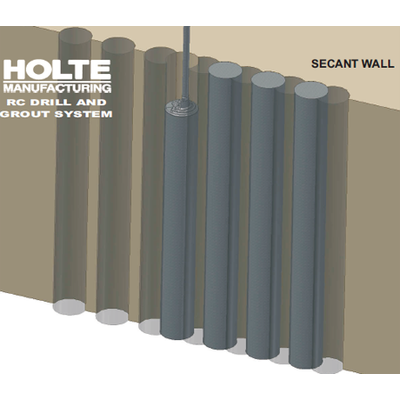

Holte - Grout Through Technology

Ready to Grout: Secant, Micropiles, Pilings, and more. Grout Through technology comes standard in all of our down hole hammers. Traditional check valves in the top are distributed around the bottom of the inner barrel instead. With Holte valving technology, DHHs minimize entry of water and debris into the operating portion, creating extended hammer life. This innovation also facilitates grout pumping into the hole. Grout flows down the evacuation center of the dual wall Drill Pipe, Hammer, and Bit. In overburden conditions, the grout can serve as the casing. Holte Top Head Drives can be ordered ready to Grout or we can modify many existing drives for Grout Through.

Holte - Cuttings Discharge Systems for Reverse Circulation Drilling

When the cuttings make it to the surface they are ideally moving somewhere between 6,000 – 12,000 ft/min. To direct the spoils into a discharge hose or containment unit it is essential to change direction somewhere around 150-180 degrees. In a reverse circulation system this is the most heavily worn piece of tooling as air, sand and gravel continually follow the same path around the corner causing severe wear and fatigue. Without thoughtful design, manufacturing and heat treatment it is obvious that standard elbows are ineffective.