Holte Manufacturing products

Reverse Circulation

Holte - Grout Through Technology

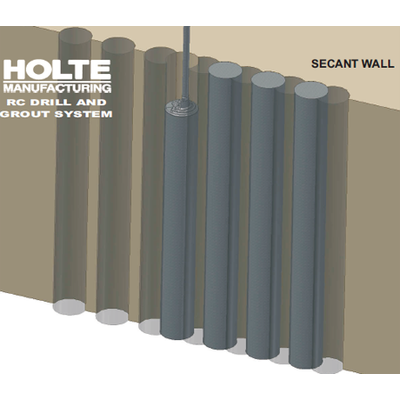

Ready to Grout: Secant, Micropiles, Pilings, and more. Grout Through technology comes standard in all of our down hole hammers. Traditional check valves in the top are distributed around the bottom of the inner barrel instead. With Holte valving technology, DHHs minimize entry of water and debris into the operating portion, creating extended hammer life. This innovation also facilitates grout pumping into the hole. Grout flows down the evacuation center of the dual wall Drill Pipe, Hammer, and Bit. In overburden conditions, the grout can serve as the casing. Holte Top Head Drives can be ordered ready to Grout or we can modify many existing drives for Grout Through.

Holte - Cuttings Discharge Systems for Reverse Circulation Drilling

When the cuttings make it to the surface they are ideally moving somewhere between 6,000 – 12,000 ft/min. To direct the spoils into a discharge hose or containment unit it is essential to change direction somewhere around 150-180 degrees. In a reverse circulation system this is the most heavily worn piece of tooling as air, sand and gravel continually follow the same path around the corner causing severe wear and fatigue. Without thoughtful design, manufacturing and heat treatment it is obvious that standard elbows are ineffective.

Reverse Circulation Bits

Precision hardened keys are lighter weight and facilitate short shank lengths. Shank design gives highest Piston-to-Bit weight ratio—maximizing button face energy. Airflow channel design and control minimizes Bit face plugging and eliminates unwanted pressurization of surrounding formations. Custom and standard sizes up to 43” diameter. Full Gauge Underreamers for Overburden conditions.

Holte - Reverse Circulation Top Head Drives

Ready for Reverse Circulation Top Head Drives. RC exhaust through the center of the Top Head permits max drill pipe length and passes larger cuttings. Less tool wear means less replacement than a side discharge swivel. Compact 3000 series Top Head or versatile and powerful 6000 series Top Head.