- Home

- Companies

- HOLZAMMER Gruppe

- Products

HOLZAMMER Gruppe products

Plastics Technology

The plastics technology division specialises in the production of high-quality housing modules and trim parts. Our internationally based customers from the areas of medical and laboratory technology, the automotive industry and the construction and energy sectors value our overall expertise in development, injection moulding, surface finishing and assembly all from a single source. Thanks to three production sites in Bavaria, Thuringia and the Czech Republic, we increase delivery reliability with our risk management. We also have environmental certifications and produce our own green electricity and heat with PV and CHP. Heat recovery systems further improve our ecological footprint. We do not process any PVC for reasons of environmental protection. Our strict quality assurance regularly subjects our products to numerous defined tests. For example, coatings are tested in a special light chamber and measurements are performed for colour fidelity and layer thickness.

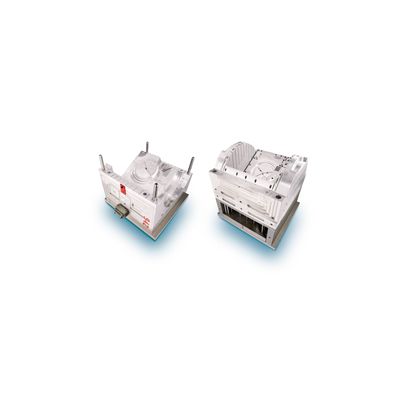

Mould Making

At the main factory in Sengenthal, we build ultra-precise tools for thermoplastic injection moulding. Whether for thermoplastic foam injection moulding or compact injection moulding. Our focus is on producing large tools (in steel/aluminium combinations or all-steel constructions) up to a weight of 15 tonnes and a maximum size of 2,000 mm x 2,000 mm x 1,500 mm. Through preventive maintenance and repair of the injection moulding tools, our mould making can not only ensure smooth in-house operation, but can also offer this service for third-party tools as well. Combined with our in-house engineering department, we realise customer-specific jigs, control gauges and all types of foam and deep-drawing moulds. With our prototype construction and as a subcontractor for all processing steps, we round off our comprehensive mould making offering.

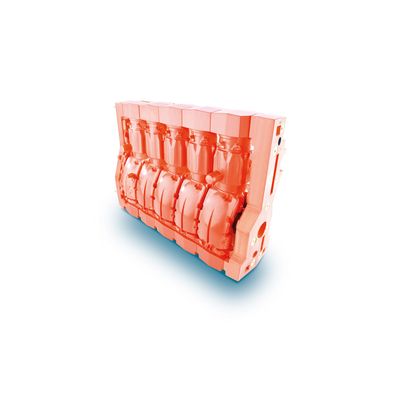

Model Making

We at HOLZAMMER have geared our technical model making to typical industry requirements. Customers of this division are mainly foundries and the internal divisions of the HOLZAMMER Group for downstream production processes. With a high degree of skill, innovative craftsmanship and expertise, our professionals use machines to create jigs made of various plastics, synthetic resins and metals. With these jigs and the copies made of foundry sand (moulding sand), our customers produce grey cast iron bodies, for example for motors and much more. As a service for external companies and own use, we also produce design and visual models as well as small series and samples for various applications.