- Water Treatment - Seawater Treatment -Chlorinators

- Water Treatment - Seawater Treatment - Dechlorinators

- Water Treatment - Potable Water Treatment - Brominators

- Water Treatment - Potable Water Treatment - Mixed-Oxidant Electrolytic Disinfectant Generators (MEDGs)

- Compressed Air Treatment - Membrane Air Dehydrators

- Compressed Air Treatment - Condenser-Filter Air Dehydrators

- Compressed Air Treatment - Air Control Panels

- Compressed Air Treatment - Filters

- Moisture Measurement

Howell Laboratories, Inc. products

Water Treatment - Seawater Treatment -Chlorinators

Howell - Chlorinators

Provides point-of-use protection against bio-fouling in marine equipment. Easily set up in a machinery space near a seawater intake. Typical applications include heat exchangers, ship seawater systems, engine cooling systems, and electronic component skids. Portable and ideal for temporary maintenance applications, but also designed for continuous operation in permanent installations.

Water Treatment - Seawater Treatment - Dechlorinators

Howell - Dockside Dechlorinators

Easily installed dockside near the discharge of any cooling system where chlorine is used to prevent bio-fouling of the cooling water. Typical applications include heat exchangers, ship seawater systems, engine cooling systems, and electronic component skids. Ideal for temporary maintenance applications or continuous operation in permanent installations.

Water Treatment - Potable Water Treatment - Brominators

Howell - Potable Water Brominator

Consists of two rugged, below-deck, bulkhead-mounted, brominator assemblies, manifolded together with flexible hose. All-bronze pump and corrosion-resistant fittings used throughout. Storage tank alignment is via solenoid valves activated by a switch on the control panel, which also includes pump start/stop, tank selector switch, and bromine feeder status indicator. Time totalizers keep track of total cartridge usage. Our patented Total Bromine Control System is available as an option with this unit. This system automatically controls the bromine level in the ship’s water storage tanks and alerts ship’s personnel when the bromine cartridges are depleted.

Howell - Proportioning Brominator

Consists of a bulkhead-mounted brominator assembly. The unique cartridge housing is manufactured from a high-strength plastic that will never corrode. Combined with the corrosion resistant fittings used throughout the unit, reliable service and long life are ensured. A water meter keeps track of cartridge usage.

Water Treatment - Potable Water Treatment - Mixed-Oxidant Electrolytic Disinfectant Generators (MEDGs)

Howell - Mixed-Oxidant Electrolytic Disinfectant Generators

Designed to be capable of disinfecting two sources of water simultaneously using an injection process, with minimal operator attention. Electrically operated, package-type (bulkhead-mounted) unit ready for operation (turn-key system) with a footprint of 48 inches wide x 12 inches deep x 48 inches high. Uses granular or pellet salt (sodium chloride) and potable water as inputs to produce a concentrated disinfectant solution in an electrolytic cell. The disinfectant solution is metered into the discharge from the ship’s desalination plants as an initial disinfectant and/or metered into recirculated water from the ship’s potable water tanks to replenish the level of disinfectant in the tanks.

Compressed Air Treatment - Membrane Air Dehydrators

Howell - Membrane Air Dehydrator

Designed for continuous, automatic operation. Moisture is removed by an array of BEKO DRYPOINT™ membrane modules. Solid contaminants and oil aerosol are removed by mechanical filtration.

Compressed Air Treatment - Condenser-Filter Air Dehydrators

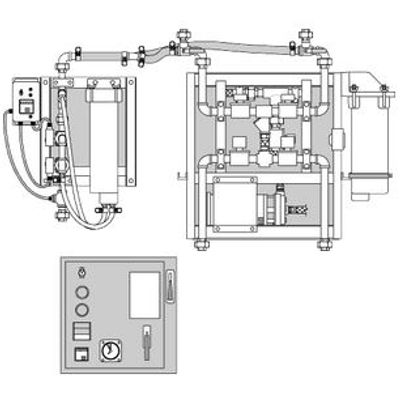

Howell - Low-Pressure Dry Air Condenser-Filter

Selected for the LHD 2-4 class, the Model 7300 Mk II low-pressure air dehydrator (LPAD) is designed to remove water vapor from low-pressure compressed air systems. The air delivered by this dehydrator is intended for use in control systems such as automatic combustion control, or in any low-pressure air system where it is desirable to eliminate moisture. Generally, the air delivered by this dehydrator is NOT of a quality adequate for use in electronics purging. Moisture removal is achieved by cooling the air stream with the ship’s chilled water. The cooled air releases moisture by condensation. The condensate is mechanically separated from the air stream and drained to the LPAD’s trap-dump valve.

Compressed Air Treatment - Air Control Panels

Howell - Air Control Panels

Air pressure is regulated by two (or, for the -G531, one) pressure regulators. Flow rate of air being delivered to the using equipment is measured by a direct-reading float-in-tube flowmeter.

Compressed Air Treatment - Filters

Howell - Oil Removal Filter

Removes oil from low pressure air. Automatic (except the manual drain valve). Requires no electrical power for operation, and has no moving parts except for the manual drain valve.

Moisture Measurement

Howell - High-Pressure Dew Point Monitor & Alarm

The Model 7149 high-pressure dew point monitor and alarm system is designed to provide a simple, reliable method of measuring the dew point (moisture content) of high-pressure (up to 5000 psig) dry air systems. It is a variation of the system incorporated in our high pressure desiccant air dehydrators. Here, it is used as a stand-alone device, downstream of an air dehydrator whose built-in monitor/alarm system is unreliable or no longer supported by the original manufacturer, or in conjunction with an inter stage membrane dehydrator (IMD) not containing its own dew point monitor. The fi rst installation with an IMD is on USS MAHAN, DDG 72. Fittings furnished as standard allow easy installation at the end of the HPAC discharge hose.