Hughes Safety Showers - A Justrite Group Company

- Home

- Companies

- Health and Safety

- Workplace Safety

- Hughes Safety Showers - A Justrite ...

Hughes Safety Showers - A Justrite Group Company

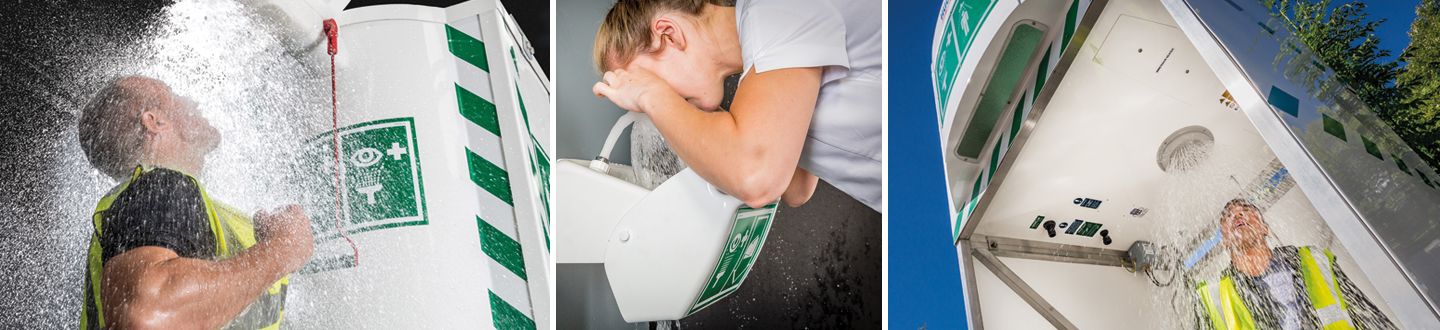

Hughes Safety Showers is Europe´s largest manufacturer of emergency safety showers, eye/face wash and decontamination equipment designed to operate across all industries regardless of location, climate or local hazards. With offices and manufacturing facilities in the UK, USA, Canada, Germany and the Middle East, plus a network of authorised distributors worldwide, you’re in safe hands with Hughes Safety Showers.

Company details

Find locations served, office locations.

- Business Type:

- Manufacturer

- Industry Type:

- Workplace Safety

- Market Focus:

- Globally (various continents)

- Year Founded:

- 1968

This company also provides solutions for other industrial applications. Please, visit the following links for more info:

Industries Served

- Agriculture

- Agriculture

- Chemical & Pharmaceuticals

- Construction & Construction Materials - Construction Safety

- Defense

- Energy

- Energy

- Environmental

- Food and Beverage

- Food and Beverage

- Government

- Health and Safety

- Health and Safety - Emergency Response

- Health and Safety - Hazardous Substances

- Health and Safety - Oil Spills

- Health and Safety - Workplace Safety