Hunan Kingcera Engineering Co.,Ltd products

Wear Resistant Ceramic Liner

Kingcera - Ceramic Wear Liners Backed Steel Plate

The ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength 7mm nature rubber sheet and 6mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance.

Kingcera - Ceramic Tiles

This ceramic tile is usually directly bonded on the inner wall of equipment by our high-strength-temperature-resistance inorganic epoxy adhesive.

Kingcera - Ceramic Rubber Wear Liner

Ceramic rubber wear liner is using the heat pressing to vulcanize the high alumina ceramic and rubber together. It can be installed onto the equipment surface by adhesive directly. It has both the advantage property of ceramic’s high hardness and rubber’s impact resistance ability.

Kingcera - Ceramic Steel Wear Liner

Product Structure:Ceramic steel wear liner using the ceramic liners bonded on the steel plate directly with the high-strength-temperature resistant inorganic adhesive, connected with bolts and nuts.

Wear Resistant Ceramic Lined Pipe Fitting

Kingcera - Ceramic Tile Lined Pipe

This kind of ceramic tile lined pipe consist of three parts (steel pipe + adhesive + ceramic tiles), the steel pipe is made of seamless carbon steel pipe. The ceramic tiles are 95% high alumina, and the bonding is high temperature epoxy adhesive up to 350oC.This kind of pipe are suitable for the powder transport without tile falling off or aging working under 350oC for long time. The service life span is 4 to 5 times than normal steel pipe.

Kingcera - Weldable Ceramic Tile Lined Pipe

With self-locking shape ceramic tiles installed into the bend or pipe by inorganic adhesive and as well as stud welding. This solution can prevent the tiles from high abrasion as well as falling off in high temperature under 750℃.

Kingcera - Ceramic Sleeve Lined Pipe

The ceramic tube or ceramic sleeve sintered as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive. The ceramic sleeve lined pipe has a smooth inner wall, excellent tightness as well as good wear and chemical resistance ability.

Wear Resistant Ceramic Lined Equipment

Kingcera - Ceramic Lined Cyclone

The material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.

Ceramic and Rubber Pulley Lagging

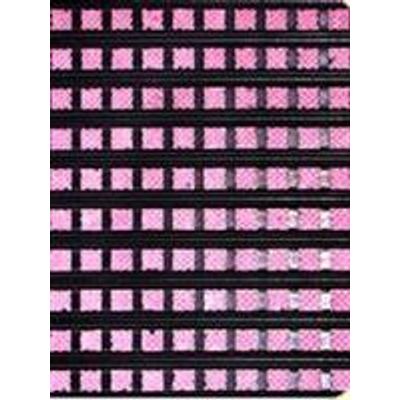

Kingcera - Ceramic and Rubber Pulley Lagging

Rubber lagging in belt pulley is usually used for transporting the mixture of coal and ore and usually under continuous operation for long time. This requires the belt pulley to be highly abrasion resistance、 highly stretching resistance and highly tear resistance. Drive pulleys can also be affected by weather if they are working outdoor(like rusting、 sludge).