- Home

- Companies

- Hydria Water AB

- Products

- Sludge Scrapers

- VA-Teknik - Fine Bubble Membrane Diffusers

- VA-Teknik - Lamella Sedimentation

- VA-Teknik - Trickling Filter Equipment

- VA-Teknik - Weirs and Scumpipes

- Mellegard & Naij - Screens & Fine Screens for Water

- Mellegard & Naij - Pre Treatment Units for Wastewater

- Mellegard & Naij - Wet Waste Screenings Handling

- Mellegard & Naij - Sludge Dewatering

- Mellegard & Naij - Grinder

Hydria Water AB products

Sludge Scrapers

VA-Teknik - Plastic Chain Scraper

VA Teknik’s plastic chain scraper is a proven product that has been on the market for more than 40 years. With thousands of installations from North to South and east to west in all corners of the world VA Teknik possesses extensive expertise. We offer you reliability and consistency with our well-engineered chain scrapers. A solid performing product where continuous development work is conducted to make the plastic chain scraper even better.

VA Teknik - Plastic Chain Operation Sludge Scrapers

The maintenance of sludge scrapers is various depending on configuration and type. The main activities when completing maintenance of these mechanical machines are the transmission chain tensioning and greasing. The previous generations of scrapers are mostly of steel chain type configurations which need a lot of greasing, often there is oil escape which increases wearing on the steel roller chain / sprockets and contaminates the water. The wearing increases maintenance costs and the oil leakage causes a reduced efficiency of the treatment, in worst case there could be a major failure.

VA Teknik - Grit Trap Scraper

VA Teknik’s grit trap scrapers are based on the same principal as our well-known plastic chain & flight scrapers, which have been on the market for over 40 years. We have successfully installed chain & flight scrapers in aerated grit traps using our plastic chain and stainless steel scraper flights. Besides excellent corrosion resistance, the plastic chain provides a very lightweight and high capacity grit removal unit.

VA Teknik - Rotating Sludge Scraper

These machines are manufactured to a basic design and are mainly made of stainless steel. Our full-bridge and semi-bridge rotating sludge scrapers are of latticework type. There are a variety of configurations, with or without supplementary functions. The scrapers can be peripheral driven full-bridge scrapers, semi-bridge scrapers or central driven.

VA Teknik - Model PFT - Picket Fence Sludge Thickener (Gravity Thickener)

These machines are fabricated in robust designs usually made of stainless steel. Steel bridges or concrete slabs are used to carry drive unit system. There are a variety of configurations, with or without supplementary functions.

VA Teknik - Vertical Chain Sludge Scraper

VA Teknik’s Vertical Chain Scraper is a product that is primarily designed to simplify maintenance at the many small, unmanned purifying plants, referred to as Dortmund tanks. This scraper can also be used at larger treatment plants inside the rectangular clarification tanks sludge pits to ensure that the sludge settles all the way to the suction point.

VA Teknik - Cable Driven Scraper Cart

VA Tekniks cable driven scraper cart was very common before but still some treatment plants use them. The cart is driven by torque limited cable drums mounted on same shaft. The cart runs smoothly on wheels on the bottom of the tank and is guided on a beam which keeps it on track. The scraper flight flips up and down with fixed stops at each end of the tank. All machines are delivered together with an electronic overload protection.

VA-Teknik - Fine Bubble Membrane Diffusers

VA Teknik - Fine Bubble Membrane Diffusers

FlexDisc and RexFlex diffusers cover various ranges and are high efficient disc diffusers with EPDM-membranes.

VA-Teknik - Lamella Sedimentation

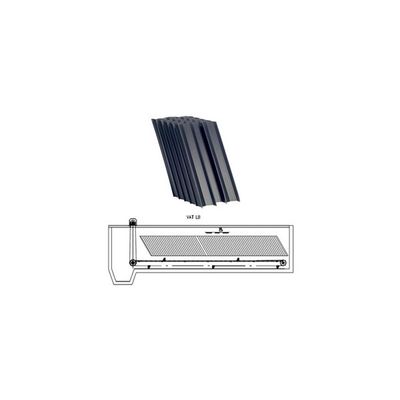

TUBEdek - Lamella Sedimentation System

Enexio’s lamella sedimentation system TUBEdek has been a successful investment at many municipal and industrial treatment plants.

VA-Teknik - Trickling Filter Equipment

VA Teknik - Rotating Distributors

Energy efficient waste water treatment is the future. Biological treatment and nitrogen ammonia removal by use of trickling filters is both an environmental friendly and cost efficient process. Trickling filters are returning in popularity due to the fact that activated sludge processes are significantly higher in operational costs than a pump required for operating a rotating distributor. VA Teknik rotating distributors for trickling filters are a premium class distributor designed for excellent performance and can handle high variation flowrates. The distributor operates together with all kinds of filter media.