Hardness, Case Depth, Material Verification

ibg - Masterpiece Eddy Current Structure Testing for Demanding Systems Integration

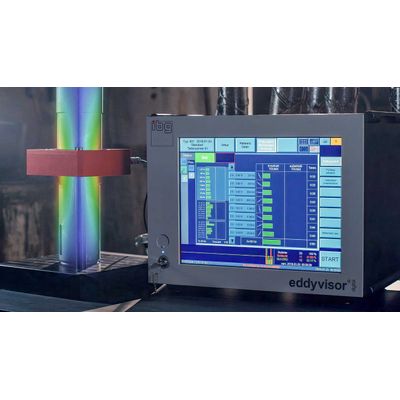

The Eddyvisor S is a cutting-edge digital eddy current test instrument designed for non-destructive evaluation of mass-produced parts, metal components, and semi-finished products. Capable of determining material properties such as hardness, case depth, structure, tensile strength, heat treatment condition, or alloy composition, the Eddyvisor S employs ibg's Preventive Multi-Frequency Technology for precise and reliable measurements. This versatile device offers a high-performance, modular design with up to 32 structure test channels in a compact form factor. Its ergonomic touchscreen interface ensures straightforward operation and quick access to all functions and test results. The device's digital processing capabilities leverage unique processors for signal stabilization immediately following the pre-amplifier stage. Compatible with standardized coils, probes, and system components globally, the Eddyvisor S is suitable for new testing applications as well as upgrading existing production machinery to integrate state-of-the-art eddy current technology. Additionally, it is available in variant configurations like the Eddyvisor SC for combined structure and crack testing and the Eddyvisor C focused on crack and grinder burn testing.

ibg - Digital Eddy Current Test Instrument

The eddyliner S is a digital eddy current test instrument designed for one-channel nondestructive testing of metal components, mass-produced parts, and semi-finished products utilizing Preventive Multi-Frequency Technology (PMFT). It examines material properties such as hardness, case depth, microstructure, tensile strength, heat treatment conditions, and alloy composition. Known for its compact design and ease of operation, the eddyliner S provides reliable eddy current testing through a user-friendly touchscreen interface. Fast calibration is facilitated by ibg's 'good part only' calibration concept, allowing the system to be set up within minutes. This process involves recording eddy current signals from a set of good reference parts, automatically generating tolerance zones that encompass their metallurgical magnetic fingerprints across all PMFT test frequencies. The system is capable of seamless integration with existing ibg equipment, supporting all coils and probes of the ibg system family. Digital signal processing with specialized processors ensures highly stable, accurate test results immediate after the signal is pre-amplified.