ICM, Inc. products

Process Technologies and Feed Products

ICM - Model BTS - Base Tricanter System Separates

The Base Tricanter System™ separates corn distillers oil from syrup. Superior oil recovery for added revenue: ICM’s Base Tricanter System™ employs a three-phase centrifuge to separate the maximum amount of corn distillers oil from syrup.

ICM - Model SMT and SMT V2 - Selective Miling Technology

Our innovative flaking system maximizes oil production and increases ethanol yield. Exposing more starch for ethanol conversion: SMT™ and SMT V2™ unlock the maximum amount of oil and starch in a corn kernel. This patented process bolts onto your existing plant with no risk to prime operations, and it provides the platform for ICM’s FST™ and FST Next Gen™. SMT™ and SMT V2™ minimize your operational expense to make you more competitive. Start taking full advantage of every bushel and add more dollars to your bottom line. Millions more.

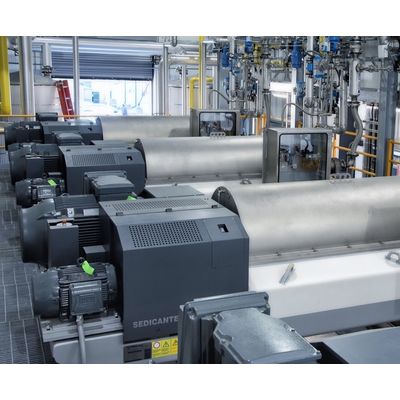

ICM - Model TS4 - Thin Stillage Solids Separation System

By removing suspended solids from the process stream, TS4™ improves dryer and evaporator capacities, minimizes energy consumption and enables the production of higher-value feed products. Improving efficiency through solids separation: By removing suspended solids from the thin stillage stream, TS4™ improves efficiency and allows equipment to process stillage at a higher feed rate while using less energy. It can help your plant reduce maintenance costs, energy costs and chemicals needed for CIP. Our patent-pending TS4™ technology also provides opportunities for creating diversified feed products.

ICM FOT - Oil Recovery System

FOT Oil Recovery™ is a proprietary two-step separation process that frees up more corn oil for recovery. The process also dewaters the whole stillage cake as it goes to the dryer, reducing your plant’s natural gas load. Maximize corn oil recovery: FOT Oil Recovery™ is a proprietary two-step separation process that frees up more corn oil for recovery. The process also dewaters the whole stillage cake as it goes to the dryer, reducing your plant’s natural gas load. By choosing to work with ICM, you tap into the benefits of our award-winning technology. Our work on FOT Oil Recovery™ was recognized at the Wichita Business Journal’s 2024 Innovation Awards.

Plant Optimizations and Expansions

ICM - Model DDE - Integrated Distillation, Dehydration and Evaporation

In ICM’s integrated distillation, dehydration and evaporation (DDE) system, each process reuses energy to increase overall plant efficiency. The distillation system uses steam and energy from the evaporation system, and the evaporation system uses heat recovered from the dehydration system and low-pressure steam. The evaporation system eliminates the land application of thin stillage by concentrating it into corn syrup, which can be added to distillers grains to increase their value.