- Home

- Companies

- Intego GmbH

- Products

Intego GmbH products

Solar

Intego - Ingot Inspection

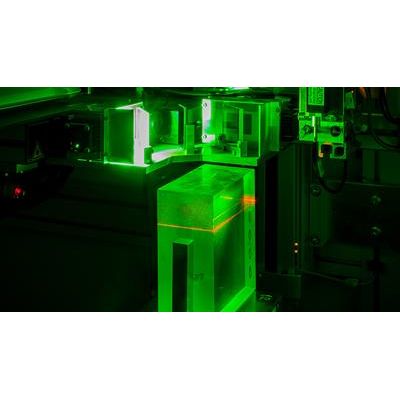

From the silicon raw material, crystal ingots are grown, which are sawn into the silicon blocks. It is reasonable to sort out faulty parts as soon as possible or, even better, to avoid processing them. Our ORION silicon block inspection systems offer a fully automated solution for inspection prior to the two process steps of polishing and wafer sawing:

Intego - Wafer Inspection System

Due to high added value in the production steps, it is important to guarantee frictionless operation and to avoid production shutdowns, particulary due to wafer breakage. Therefore, wafers with structural defects, e.g. cracks, saw marks or chippings should be detected and separated out.

Ceramics & Glass

Sirius - Brick Inspection System

Our SIRIUS brick vision systems take advantage of the well-defined surface of bricks to perform 3D measurements and high-end inspections for inclusions and crystal grains. A laser marking system is an effective completion of the tested bricks. Exact analysis of the positions of errors within the brick enables optimized cutting of wafers for coverglass or semiconductor production.

Intego - Brick Slab Inspection System

Whenever brick inspection is not feasible, inspection of pre-cut slabs is a viable option. SIRIUS slab inspection tools increase the yield and quality of the cores processed from every single slab.

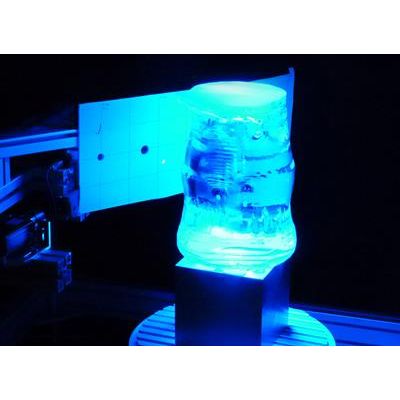

Intego - Boule Inspection System

Sapphire boules created by the Kyropoulos method have a clear but uneven surface, making optical inspection rather difficult. With advanced image processing techniques, Intego has achieved the ability to look inside the unrefined boule.

Plastics

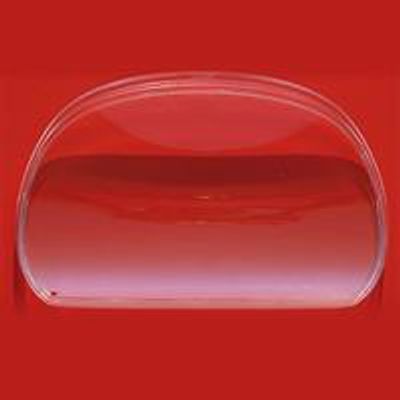

Intego - Display and Transparent Part Inspection System

Transparent parts such as covers, displays or lenses can easily be inspected with automated means. In the plastic processing sector they are normally produced by injection moulding. By using the same methods, displays or lenses of other transparent materials such as glass or sapphire can also be inspected.

Intego - Microtiter Plate Inspection System

Microtiter plates are essential today for investigating biochemical or cellular biology topics in scientific and industrial laboratories. Because of their use as storage plates for active substances, patient samples, or biomolecules, great demands are made on the manufacturing quality. The main focus here is on the quality of the bottoms of the wells, which must allow automatic evaluation of the contents during the screening of pharmaceutically active substances. As a result, manufacturing defects must be reliably identified and consistently separated out. Continuously occuring errors should be revealed quickly in order to keep rejection rates low.

Metal

Intego - Tube Inspection System

In manufacturing metal and polymer tubes, the early detection and prevention of faults is essential for quality and safety reasons. Our inspection systems are designed for a fully automated 100 % inspection rate in rough industrial environments. We offer 3D measurement systems for inner and outer tube surfaces with fast laser triangulation.

Semiconductors

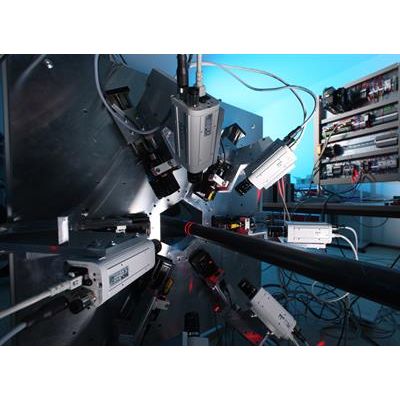

Intego - Model LEDs, OLEDs, MEMS - Microscope Scanner

The microscope scanner for the inspection of LEDs, OLEDs and MEMS is based on an automated platform, which delivers a high throughput of the parts. The basic system consists of a handling unit and a measuring unit. In the handling unit, a robot transports the wafers or substrates, which can exhibit diameters of up to 12", out of the cassettes, while in the measuring unit the samples are moved under the detector. Typically, resolutions of 0.1 μm - 5 μm are achieved in combination with illumination techniques from the UV-VIS-IR spectral range.

Electronics

Intego - Model SPICA - Thermography System

With the SPICA system Intego offers a highly sensitive laboratory system for thermography. The system is based on the SPICA IR camera, which has been specially developed by INTEGO for inspection and measurement tasks and allows fast and non-destructive inspection and localization of defects. The measurement technology and automation can be individually adapted to the different requirements of the production process.