Intensiv Filter Himenviro Technologies GmbH products

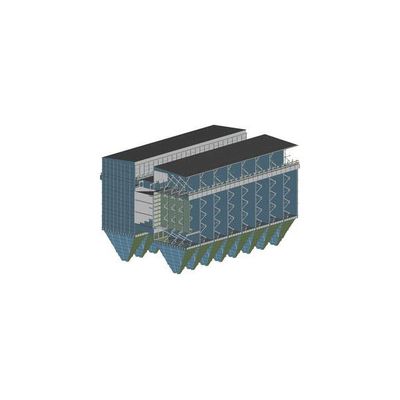

Electrostatic Precipitator for Industrial Emission Control

Electrostatic precipitators, designed by Intensiv Filter Himenviro, are crucial industrial emission-control devices used to remove fine particles from gases. Utilizing an electric charge, these precipitators target and eliminate tiny solid impurities or liquid droplets from exhaust gases found in smokestacks and flues. The technology involves charged particles being attracted to plates, ensuring an efficient collection rate of up to 99.9%. These devices have diverse applications across industries, especially in power plants, where multiple units may be deployed. Differentiated into dry and wet types, ESPs handle a range of particulate materials, from wood ash to sulfuric acid mist, adapting to various gas volumes and temperatures. Notably, dry ESPs operate at temperatures above the dew point, making them suitable for dry dust collection, whereas wet ESPs cater to exhaust systems with oily and sticky particulates. While initial costs may be high, ESPs offer low maintenance and operational costs, with benefits in cleaning efficiencies and pollutant removal. Their design incorporates features like mechanical rappers for dust removal, ionization for particle charging, and multiple configurations to meet specific industrial needs, ensuring compliance with environmental standards and reducing health risks associated with industrial emissions.

Pulse Jet Bag Filter

The Pulse Jet Bag Filter utilizes a pneumatic pulse-jet system for automatic and continuous cleaning of dust-laden bags. During a timed cycle, a burst of compressed air is directed through a venturi tube at the top of each bag, setting off a shockwave that stops the airflow and flexes the bag to dislodge accumulated dust particles. These particles then fall into a hopper for easy removal. The system is designed such that only a few rows of bags are cleaned simultaneously, ensuring no interruption to the overall airflow. The result is a highly efficient dust control or material handling unit that operates smoothly. This system is versatile, finding applications in sectors requiring robust and reliable dust extraction and air purification.

Hybrid Electro Filters

The Electro-Plus-Hybrid Filter technology by Intensiv Filter Himenviro Technologies GmbH offers a filtering solution that utilizes static electricity for particulate matter collection, ensuring higher collection efficiency and reduced pressure drop. The hybrid filter system addresses common issues like pressure drop increases due to bag clogging associated with conventional Bag Filter Systems. By forming a dendrite structure layer on the bag surface, it prevents microparticle penetration and reduces filter bag blinding, thus extending the bag’s life and enhancing filtering efficiency. The robust design makes it suitable for various industrial applications requiring high-performance filtering solutions.

Bag Filters and Filtering Separators

ProJet - Mega Process Filter

The process filter ProJet mega have been developed for dedusting large volume flows. The variety of parts of the ProJet mega series is significantly reduced while maintaining a maximum number of possible explanations. For a relatively small number of constructive primitives are solely responsible for in-line filter of 1-12 filter chambers (each with 8 injector pipes x 8-17 injectors per row) represented over 600,000 different versions. This account of the different process engineering and structural conditions is supported, which are required for process filters.

ProJet - Smart Compact Filter

With the objectives of process optimization, cost reduction and efficiency of dedusting specialist Intensiv-Filter has developed an optimized compact filter that is tailored to the particular application. Equipped with mounted fan and silencer and associated cleaning control this new compact filters are the most readily available and inexpensive dedusting solution. The ProJet smart is designed as a compact filter with dust collection chamber or top filter with optional bypass damper in a modular system and is based on four filter heads, which are combined with four filter bag lengths. Intensiv-Filter, with its filter program ProJet smart modern and tailored solutions for dedusting of flow rates 2,000 m3/h - 20,000 m3/h in particular. For each request in a variety of industries dedusting solutions can be quickly and flexibly designed and delivered. In terms of quality and durability set the new compact filter a new benchmark in industrial dedusting.

ProJet - Cleaning in Place Filter (CIP)

ProJet CIP Cleaning in Place filters are round filter for cleaning the exhaust air from spray dryers as well as for product recovery. By focusing on an increased product recovery, reducing the mounting hardware and installation surface and perfected the new CIP cleaning filter was developed. In addition, the potential of energy efficiency were taken into account, which poses a challenge to manufacturers and users of drying plants. By optimizing the drying equipment as well as the downstream units to energy costs and energy associated with the Product take-back-extraction of CO2 -emissions can significantly reduce.The development of the CIP-filter not only leads to a higher product safety, but also contributes to increased efficiency in the production process at: our result for your process optimization.

CombiJet - Bag Filter

Basically,it comes with filter systems for dust always to high deposition rates, reliability and low maintenance overhead and operating costs. The sophisticated filtering solution CombiJet combines all these requirements. Bag filter of the CombiJet series are available in a modular system in welding and bolted, and are suitable for various applications. CombiJet is standardized and based on prefabricated components and modular units. The mounting expenses are thus reduced significantly. The filter sizes vary from 25 to more than 10,000 m² filter surface. Depending on the application, the filter is cleaned in the online, offline or semi-offline method.

Conversion of Electric Filter in Bag Filter

The superior technology of bag filters has already caught up with the advantages of electrostatic precipitators. In particular, compliance with current - and in the future even more stringent - typical values for the dust emission is not observed with electrostatic precipitators. Plant operators have still propagated without braking interest in rebuilding an electrical filter system in a Bag house. Intensiv-Filter has demonstrated with a series of successful installations that convert into a bag filter the expectations of the operators and the corresponding emission standards are well below. With the intensive filter concept electric filter-system can be converted virtually into a Bag house filter. The typical conversion is done in several steps.

Filter Media

ProTex - Model CIP - Filter Media

You need to ensure high safety and quality standards in the Dedusting of your hygienically demanding processes? For this, we offer you filter bags from the newly developed ProTex CIP® filter medium. ProTex CIP® meets the requirements of the European Regulation no. 10/2011 on plastic materials and articles which are intended for contact with eatables. The default values for global migration and specific migration values are significantly lower. A declaration of conformity is issued for each hose delivery. They meet with ProTex CIP® filter media, the high safety and quality standards of European Regulations EU 10/2011, EU 1935/2004 and Commodities Regulation.

Other Products

Retrofit Mechanical Filter

Anew not always is called better. Thus it can absolutely be an advantage to modernise available filtering installations or components only or to bring to a newer and more efficient state of technology. From renewals of filter heads up to complete technical revision - Intensiv-Filter supports you not only with the choice and the retrofit of your filtering installation with mechanical cleaning, but brings this also onto the state of technology necessary for it. This way the servicing expenditure and the maintenance costs of your dust extraction plant can be reduced clearly with low capital costs.