International Erosion Control Systems (IECS) products

Cable Concrete - Articulated Concrete Block System

International Erosion Control Systems specializes in Cable Concrete®, which is one of the most advanced engineering technologies available for soil erosion control today. Cable Concrete® is an Articulating Concrete Block (ACB) system connected by cables allowing each individual block to be flexible and form to the terrain of the ground. This interconnected block system is available in four different thicknesses to provide the required stability for each project economically. Cable Concrete® has gone through extensive testing by engineering departments at three different universities: The University of Windsor, Ontario; The University of Colorado; and The University of Minnesota.

Cable Concrete - Articulated Concrete Block System

Cable Concrete G2 is an articulated concrete block revetment system, developed by International Erosion Control Systems Inc. Specifically designed for permeable paving applications such as vehicular access roads, pedestrian pathways, low flow and gentle slope applications to control various types of erosion due to water, wind, and vehicle traffic. The standard mats are 2.44m x 6.1m long (8’x20’) placed side by side to provide a protective system. The mats can easily be cut at provided cut lines to obtain lengths of 2, 3 and 4 metres when required. The mats consist of concrete blocks interlocked by polyester or stainless steel cables, which are poured through each block in both directions. Spacing between blocks provide ± 40% opening for vegetation or granular backfill. The blocks typically have 190.5mm (7.5”) hexagonal top faces and 228.6mm (9.0”) hexagonal bottoms.

IECS - Retaining System

LG Retaining System is a large stackable concrete unit that creates a solid and stable retaining wall. These walls are very strong, and also easy to install. Due to their simplicity, effectiveness, and attractive finish, LG Retaining System is the contractors choice. LG Retaining System is available in a variety of shapes and sizes and can be customized to suit unique site specifications.

OPSD - Precast Headwalls

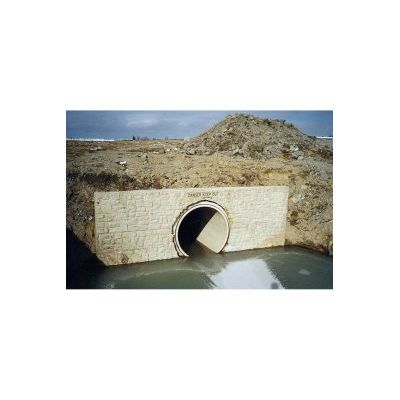

In today’s evolving world of high speed construction, we are all looking for effective ways to save time and money. Precast Headwalls are a great solution to achieve this, and are described as a retaining wall at the inlet or outlet of a pipe or culvert. We ensure unparalleled quality with our Precast Headwalls, as International Erosion Control Systems is a pioneer in the Precast Headwall market. In 1996 we introduced the first ever OPSD 804.04 style Precast headwall, and have since continued to develop different systems to construct this unit to accommodate customers’ needs on a per job basis. We offer a wide spectrum of standard and modified walls which conform to provincial standards. IECS Precast Headwalls can be customized to fit multiple pipe openings, box culverts and horizontal elliptical applications. Our headwalls are available with galvanized or epoxy coated grate, which is attached during manufacturing (OPSD 804.05) and Danger Keep Out warning (OPSD 3940.150).

OPSD - Precast Headwalls

In today’s evolving world of high speed construction, we are all looking for effective ways to save time and money. Precast Headwalls are a great solution to achieve this, and are described as a retaining wall at the inlet or outlet of a pipe or culvert. We ensure unparalleled quality with our Precast Headwalls, as International Erosion Control Systems is a pioneer in the Precast Headwall market. In 1996 we introduced the first ever OPSD 804.04 style Precast headwall, and have since continued to develop different systems to construct this unit to accommodate customers’ needs on a per job basis. We offer a wide spectrum of standard and modified walls which conform to provincial standards. IECS Precast Headwalls can be customized to fit multiple pipe openings, box culverts and horizontal elliptical applications. Our headwalls are available with galvanized or epoxy coated grate, which is attached during manufacturing (OPSD 804.05) and Danger Keep Out warning (OPSD 3940.150).

OPSD - Precast Headwalls

In today’s evolving world of high speed construction, we are all looking for effective ways to save time and money. Precast Headwalls are a great solution to achieve this, and are described as a retaining wall at the inlet or outlet of a pipe or culvert. We ensure unparalleled quality with our Precast Headwalls, as International Erosion Control Systems is a pioneer in the Precast Headwall market. In 1996 we introduced the first ever OPSD 804.04 style Precast headwall, and have since continued to develop different systems to construct this unit to accommodate customers’ needs on a per job basis. We offer a wide spectrum of standard and modified walls which conform to provincial standards. IECS Precast Headwalls can be customized to fit multiple pipe openings, box culverts and horizontal elliptical applications. Our headwalls are available with galvanized or epoxy coated grate, which is attached during manufacturing (OPSD 804.05) and Danger Keep Out warning (OPSD 3940.150).

OPSD - Precast Headwalls

In today’s evolving world of high speed construction, we are all looking for effective ways to save time and money. Precast Headwalls are a great solution to achieve this, and are described as a retaining wall at the inlet or outlet of a pipe or culvert. We ensure unparalleled quality with our Precast Headwalls, as International Erosion Control Systems is a pioneer in the Precast Headwall market. In 1996 we introduced the first ever OPSD 804.04 style Precast headwall, and have since continued to develop different systems to construct this unit to accommodate customers’ needs on a per job basis. We offer a wide spectrum of standard and modified walls which conform to provincial standards. IECS Precast Headwalls can be customized to fit multiple pipe openings, box culverts and horizontal elliptical applications. Our headwalls are available with galvanized or epoxy coated grate, which is attached during manufacturing (OPSD 804.05) and Danger Keep Out warning (OPSD 3940.150).

Specialty Precast

IECS Continues to set the bar in the world of specialty precast challenges, offering segmental systems for most structural designs. Pre-casting the typical “cast-in-place” specification is a solution that can save the construction world time and money by greatly reducing shoring, dewatering and weather variables. All IECS’ products are manufactured indoors under a controlled environment ensuring the quality out company has been built on for over three decades. Continuing to reinvent what precast can be IECS welcomes all challenges, big or small and have shown time and again the ability to think “outside the box” and manufacture to site specific needs and obstacles.