- Home

- Companies

- ISRA VISION AG

- Products

ISRA VISION AG products

Applications - Cell - Inline Process Monitoring

ISRA - Inline Optical Inspection System

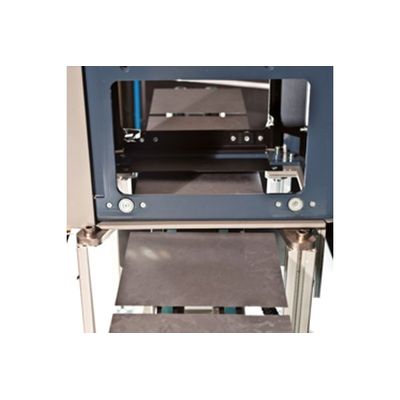

The TEX-Q inspection system precisely monitors the cell surface for contamination and defects, while also checking the texturing for homogeneity and reflectivity. It features high-performance line-scan cameras that uncover defects like long-term drifts or overetching of grain boundaries, even at a throughput of several thousand wafers per hour. The cameras can also be fitted beneath the roller transport.

Solar - Applications - Modules

ISRA - Electroluminescence PV Module Inspection System

MOD-Q combines various inspection channels to provide a comprehensive overview of the manufacturing process. It reliably detects and classifies defects on solar modules. The system guarantees detailed module inspection, even at throughput rates of up to 180 modules per hour.

Laboratory Equipment

GP - Edge Isolation TE Sting for Wafers

Situation: After diffusion (standard or one-sided), there is usually a parasitic emitter present on the rear side of the cell, which is interconnected with the front across the edges. Application of cell contacts without accounting for the parasitic emitter leads to low parallel resistances, often completely shunted cells. For edge isolation, plasma etching as well as wet chemical etching directly after diffusion is applied.