JVI Vibratory Equipment products

Vibratory Feeders

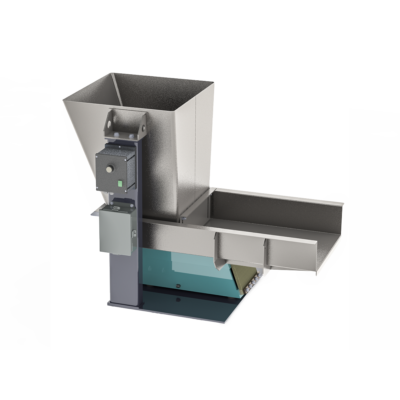

JVI - Vibratory Dosing Feeders

JVI Vibratory Equipment specializes in creating vibratory dosing feeders designed for precise feed rates and accurate bulk material processing. These feeders are equipped with an advanced electromagnetic drive that allows for zero to 100% feed rate adjustability and instant start/stop operation, making them exceptionally reliable for mixing, dosing, and batching applications. Renowned for their maintenance-free design, JVI's vibratory dosing feeders are factory-tuned, eliminating the need for field adjustments. They are capable of feeding materials from grams per minute to tons per hour, accommodating both light-duty and heavy-duty applications. Enhanced with features like custom control packages and integrated hoppers, these feeders can be adapted to unique process requirements. They are suitable for a wide range of industries, including food & beverage, plastics, ceramics, chemicals, and cosmetics. JVI's in-house engineering team ensures these feeders are custom-designed to meet the specific environmental and material conditions of each customer's application, making them an indispensable component in efficient and accurate bulk material handling.

Vibratory Screens

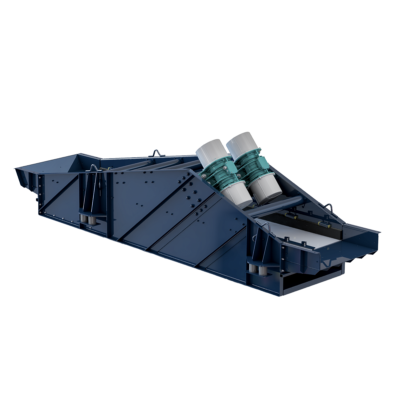

JVI - Vibratory Classifying Screens

JVI Vibratory Equipment, founded in 1991, specializes in designing and manufacturing advanced vibratory equipment for bulk material processing. An engineering-driven company, JVI offers innovative vibratory classifying screens that ensure precise particle size separation for various industrial processes. These linear vibrating screens effectively handle large volumes of bulk material, delivering accurate and consistent sizing required for downstream equipment. With multiple drive options, including electromechanical motors, electromagnetic drives, and exciter drives, the screens can be tailored to various production volumes. JVI's classifying screens cater to industries such as mining, aggregates, steel, recycling, chemicals, food, and pharmaceuticals. They offer modular screen deck configurations, discharge setups, and robust construction materials to match specific application needs. For added customization, options include food-grade finishes, explosion-proof certifications, and multi-deck designs for layered material separation. JVI's in-house Material Testing Lab and dedicated engineering team collaborate with clients to create optimized, reliable, and low-maintenance screening solutions, thereby enhancing throughput and operational efficiency.

JVI - Vibratory Grizzly Screens

JVI Vibratory Equipment specializes in the design and manufacture of robust, low-maintenance vibratory equipment for bulk material processing. Their vibratory grizzly screens are designed to enhance productivity by efficiently separating oversized material from on-spec particles, making them suitable for downstream processes. These heavy-duty screens are adaptable across multiple industries, including mining, recycling, and steel, providing reliable, continuous operation even in the harshest conditions. The grizzly screens feature a unique cascading finger design, driven by electromechanical motors, that ensures effective screening and long service life. Each screen is customizable to meet specific application requirements, including various abrasion-resistant liners and explosion-proof certifications. With over 30 years of engineering expertise and a dedicated material testing lab, JVI ensures optimized screen performance tailored to customer needs, promoting throughput and profitability while minimizing maintenance.