- Home

- Companies

- JVI Vibratory Equipment

- Products

- JVI - Vibratory Classifying Screens

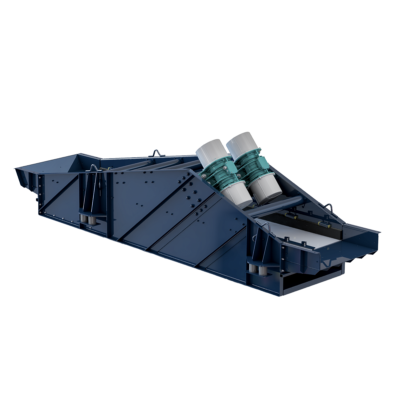

JVI - Vibratory Classifying Screens

JVI Vibratory Equipment, founded in 1991, specializes in designing and manufacturing advanced vibratory equipment for bulk material processing. An engineering-driven company, JVI offers innovative vibratory classifying screens that ensure precise particle size separation for various industrial processes. These linear vibrating screens effectively handle large volumes of bulk material, delivering accurate and consistent sizing required for downstream equipment. With multiple drive options, including electromechanical motors, electromagnetic drives, and exciter drives, the screens can be tailored to various production volumes. JVI's classifying screens cater to industries such as mining, aggregates, steel, recycling, chemicals, food, and pharmaceuticals. They offer modular screen deck configurations, discharge setups, and robust construction materials to match specific application needs. For added customization, options include food-grade finishes, explosion-proof certifications, and multi-deck designs for layered material separation. JVI's in-house Material Testing Lab and dedicated engineering team collaborate with clients to create optimized, reliable, and low-maintenance screening solutions, thereby enhancing throughput and operational efficiency.

Vibratory classifying screens separate closely sized particles for reliable product quality.

Delivering accurate material cut sizes for downstream processes.

Vibratory classifying screens separate particles into desired cut sizes using principles of probability and stratification. These vibrating screens – also called linear classifying screens – are designed for applications that require specifically-sized material for handling by the next equipment in the industrial process.

They deliver accurate, consistent particle size separation and are capable of continuous operation and high throughput rates. Vibratory classifying screens are scalable to accommodate variable production volumes and can be manufactured in a wide variety of materials, screen deck arrangements, discharge configurations, and mounting arrangements. Drive options include electromechanical motors, electromagnetic drives, exciter drives, and dosing drives. They are designed to handle large volumes of bulk material.

JVI vibratory classifying screens are used widely across many industries, including mining & aggregates, steel, recycling, plastics, chemicals, food & beverage and more.

We offer an extensive array of drive and motor types to handle light-duty applications, such as food and pharmaceuticals, up to heavy-duty applications, including mining, aggregates, steel, and recycling.

Accurate, consistent particle separation. Tailored for each application.

Maximized Screening Efficiency

Each vibratory classifying screen is designed to maximize the probability that the correct particle size does pass through the screen deck, delivering optimal particle size separation.

Each screen is designed and manufactured to meet the requirements of the work envelope, the process, and the types of bulk material to be screened.