- Home

- Companies

- KC Cottrell, Inc

- Products

KC Cottrell, Inc products

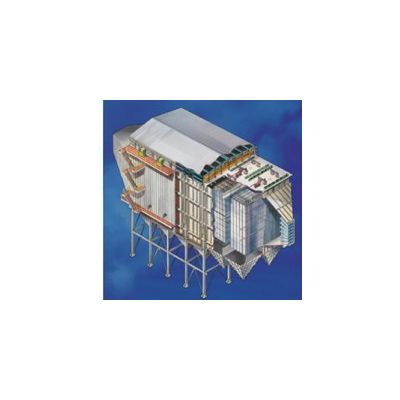

Dry Electrostatic Precipitators

KC Cottrell electrostatic precipitators are renowned for their high efficiency and low operating costs. They are of robust construction, proven design and feature access at all levels to internals and rapping gear. KC Cottrell companies have over 200 years combined experience in the design and construction of electrostatic precipitators.

Wet Electrostatic Precipitators

KC Cottrell wet-type electrostatic precipitators operate on saturated gas streams, i.e. at gas temperatures equal to or below the water dew point of the gas stream. In the ‘Wet’ units, the rapping gear associated with ‘Dry’ units is replaced by an intermittent wash-down system using water to remove the deposits from the collector sheets. KC Cottrell has supplied over 750 ‘Wet’ units for a variety of applications worldwide.

These include both vertical and horizontal gas flow precipitators.

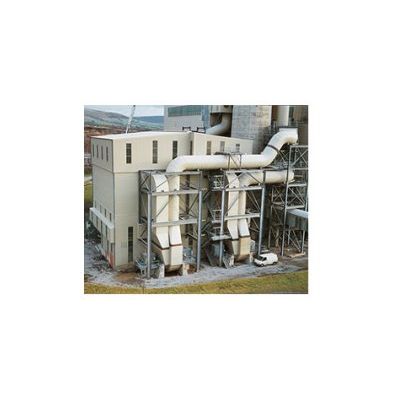

Fabric Filters

KC Cottrell Pulse-Jet Fabric Filters are used throughout industry on a wide range of applications. They provide sound technical and commercially attractive solutions on processes which demand high collection efficiencies with related low dust emissions. These filters require an absolute minimum of attention and maintenance.Installations range from a small single compartment unit up to multi-compartment systems operating as part of a complex, total gas cleaning plant often involving other types of air pollution control devices.

Ceramic Filters

KC Cottrell Ceramic Filters are an extension to the Pulse-Jet Fabric Filter range and can operate continuously at temperatures of 500°C and peak temperatures of 900°C. They achieve particulate emissions as low as 1mg/m³, and can operate in arduous process conditions with high acid gas concentrations. Pulse-Jet Ceramic Filters are completely unaffected by surges of temperature and are resistant to sparks and incandescent particles. Ceramic elements do not flex so there is no mechanical degradation. Like the Fabric Filter range, cleaning is by Pulse-Jet which removes the cake from the filter elements. In addition to emission control the ceramic filter is also effective for the reclamation of valuable process materials such as metals and minerals.

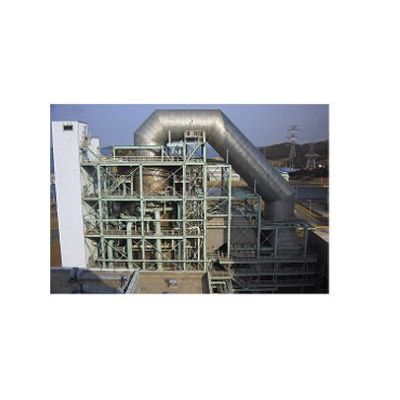

Flue Gas Desulphurisation System

KC Cottrell is able to offer FGD technology for large process applications such as power stations, steel works, and chemical plants. This high efficiency, low cost, limestone to gypsum process is well proven and is operational on many large boiler units worldwide

De-NOx Systems

Also included within KC Cottrell`s extensive portfolio are De-NOx systems which reduce harmful nitrous oxide gases. Together with our parent company, KC Cottrell, we are facing the pressing task of removing nitrous oxide (NOx) and other major pollutants, such as sulphuric acid, carbon monoxide and dioxin. The company is an experienced provider of both catalytic (SCR) and none catalytic (SNCR) reduction systems.