- Home

- Companies

- KC Cottrell, Inc

- Products

- Fabric Filters

Fabric Filters

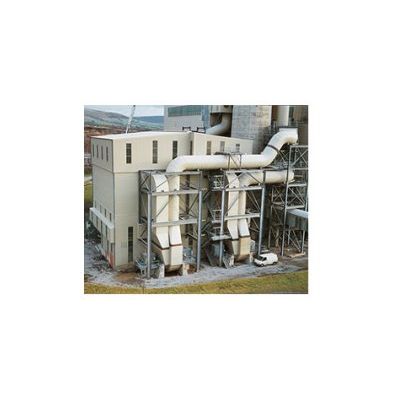

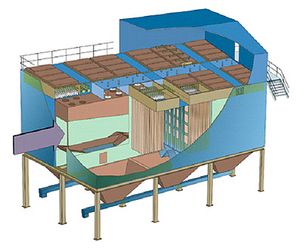

KC Cottrell Pulse-Jet Fabric Filters are used throughout industry on a wide range of applications. They provide sound technical and commercially attractive solutions on processes which demand high collection efficiencies with related low dust emissions. These filters require an absolute minimum of attention and maintenance.Installations range from a small single compartment unit up to multi-compartment systems operating as part of a complex, total gas cleaning plant often involving other types of air pollution control devices.

High Efficiency

Dust collection efficiencies of greater than 99.9% are readily attained with careful selection of filter media and operating parameters. Novel design of the inlet duct permits high inlet dust loading with only a moderate pressure loss.

Continuous Operation

Automatic effective bag cleaning using pulsed air: microprocessor controllers; "on-line" or "off-line" cleaning to suit application requirements; "on-line" maintenance option on multi-compartment units; high plant availability.

- High efficiency dust collection with low maintenance

- Optimised gas flow distribution system

- Multi-compartment concept allows flexibility of system design

- Use of standard components minimises costs

- Improved Filter Bag and Cage design

- Venturi fitted to Bag Cage improves pulse cleaning

- Intelligent control system reduces power consumption

- Easy access for filter bag change and inspection

- Operating temperatures up to 250°C

- Reference plants in excess of 1,000,000m3 per hour