- Home

- Companies

- Kimre Inc.

- Products

Kimre Inc. products

Driftor - Drift Eliminators for Cooling Towers

Drift is water lost from cooling towers as liquid droplets are entrained in the exhaust air. The drift loss is independent of the water lost by evaporation and may be expressed in units of lb/hr or percentage of circulating water flow. Drift eliminators are used to control this drift loss from the tower.

Kimre Accu-Pac - Model CDX-80 & CDX-150 - Mist Eliminators

Kimre mist eliminators are state of the art, durable, high efficiency and with cell design that will meet the most stringent mist removal specifications. Special features are included in the designs for Counterflon and Crossflon toners. Kimre mist eliminators provide ultra-Ion drift loss and are used in Cooling Toner, Evaporative Cooling, Turbine Intake Cooler, Scrubber and High Humidity Cooling systems.

Replacement Filters

Kimre, Inc. offers a complete line of fiber bed filter mist collector systems. We design and fabricate fiber bed coalescing filters for use in a wide range of applications in various industries to reduce and eliminate liquid mist emissions. Available in standard or custom- designed configurations to fit new or existing systems in the field. Our fiber bed coalescing filters offer long filter life and simplified maintenance.

Mist Eliminators

Kon-Tane - Scrubber and Tower Packing Mist Eliminators

In unit operations or gas cleaning applications, mass transfer refers to the net movement of a chemical from one phase to another. Typically, this involves the transfer of a gaseous component into a liquid component, but can be from liquid to gaseous. Some of the processes where mass transfer is performed includes absorption, scrubbing, stripping and distillation. Tower packing is typically used to provide an improved environment for the contact between the two phases and improve the mass transfer.

Kimre - Model B-GON - Mist Eliminators

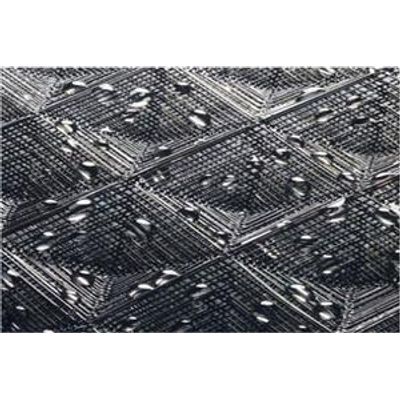

Mist elimination or “demisting” can be defined as the mechanical separation or removal of liquid droplets or mists from vapor streams. Failure to effectively capture these mists often leads to higher contaminant emissions, production losses, corrosion of downstream equipment, and increased maintenance. The most common mist elimination technologies utilized are chevron (also referred to as vane-type) separators and knitted wire-mesh mist eliminators. Chevrons are plate-type eliminators that offer high liquid handling capabilities but limited collection efficiencies for fine mist droplets below 20 microns (µm). Knitted mesh mist eliminators are constructed of wires or fibers into a randomly oriented mesh-pad structure. These mesh pad mist eliminators provide collection efficiencies for mist droplets down to 3-5 microns in size but can have limited liquid handling capabilities and are susceptible to fouling from insoluble contaminants.

Liqui-Nomix - Liquid Coalescers

Kimre’s LIQUI-NOMIX Liquid/Liquid Coalescers provide polishing of liquid streams to remove contaminant liquids to meet any industry standards. Water quality levels below 2 ppm can be easily achieved. LIQUI-NOMIX is used as a final polishing element by many of the industries’ leading Original Equipment Manufacturers (OEMs) of oil/water separators.

Kimre - Fiber Bed Filter Mist Eliminators

Fiber Bed Filters, also called Candle filters, high efficiency mist eliminator (HEME) filters and Brownian diffusion filters, are used to trap, collect and remove liquids and soluble particulate matter suspended in a gas stream. They are typically cylindrical elements where the “bed” is composed of fine fibers of media composed of various grades and density packed between two cylindical screens. The Screens (or Cages) can be constructed of various types of materials depending on the nature of the application ranging from carbon steel to corrosion resistant alloys to polymer materials. Mist laden gas passes the wall of the Fiber Bed Filters and cleaned gas exits from the opposite side. If the gas passes from the inside to the outside of the element, it is called forward flow or a sitting filter. If the gas passes from the outside to the inside of the element It is called reverse flow or a hanging filter.