- Home

- Companies

- KLa Systems, Inc.

- Products

KLa Systems, Inc. products

Kla Systems - Slot Injector system

The Kla Systems Slot Injector system is a superior jet aeration system that is specifically applied to industrial biological treatment processes where fine screening is a standard pretreatment operation in both conventional and advanced air activated sludge applications. First introduced in 1979 by Bayer AG, the Slot Injector™ is similar to a modern jet aerator but uses a slot-shaped configuration to achieve higher efficiencies.

KLa - Jet Aeration System

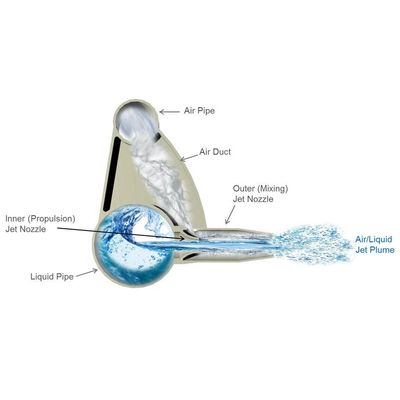

Jet Aerators transfer oxygen by simultaneously introducing large volumes of high kinetic energy liquid and air through a series of jet nozzles. The high velocity liquid exits the inner, primary jet and rapidly mixes with the incoming air in the outer jet. This intense mixing and high degree of turbulence in the gas/liquid cloud travels outward from the jet along the basin floor prior to the vertical rise of the gas bubble column to the liquid surface.

KLa Systems - Jet Mixers

Jet Mixers are widely used in both municipal and industrial wastewater treatment facilities to blend the plant influent and suspend light organic solids in circular equalization tanks. Other applications for these powerful hydraulic mixers include mixing anoxic tanks and anaerobic reactors with the latter application being for industrial waste streams only. Jet mixers are the technology of choice based on their flexibility of operation and configuration in small and large diameter tanks, the highly corrosion and abrasion resistant in-basin components, the use of simple external pumping systems, and a +20-year design life.

KLa - Complete Systems

A typical system consists of the slot injector aerators, jet mixers or jet aerators complete with in-basin piping system, back-flush system, liquid recirculation pumps and air blowers. The pumps supplied are either end suction centrifugal, submersible, or self-priming. Low pressure air is delivered by positive displacement blowers, screw compressors, multi-stage or high speed centrifugal blowers.

KLa Systems - Jet Aeration Systems

Jet Aerators transfer oxygen by simultaneously introducing large volumes of high kinetic energy liquid and air through a series of jet nozzles. The high velocity liquid exits the inner, primary jet and rapidly mixes with the incoming air in the outer jet. This intense mixing and high degree of turbulence in the gas/liquid cloud travels outward from the jet along the basin floor prior to the vertical rise of the gas bubble column to the liquid surface.

KLa Systems - Effluent Decanters

KLa Systems floating Effluent Decanters are used to draw clarified liquid from near the liquid surface of sequencing batch reactors and aerobic digesters. The design is both simple and rugged, constructed of Type 304L stainless steel for the weir, draw-off pipe, swing joint support, and stop supports. The floats used are high-impact, UV stabilized polyethylene with closed cell polyurethane foam. The swing joint is cast iron with Ni-resist bushings with nitrile O-ring seals. Other design features are an adjustable effluent port depth and a top vented air release.

KLa Systems - Back-Flush Systems

Water Environment Research Foundation (WERF) studies show that fine-pore diffusers have reduced oxygen transfer performance and increased pressure requirements over time due to clogging, and the biggest drop-off is in the first 24 months of operation.

KLa Systems - Replaced Bridge Mounted Mechanical Aeration Systems

KLa Systems is in a unique position to assist industries in meeting the challenges of production expansion and/or optimizing energy usage in their wastewater treatment facility. Out Slot Injector™ aeration system can easily retrofit all types of coarse and fine bubble diffuser systems, including conventional jet aeration systems. Higher (15-60%) oxygen transfer rates can be achieved using the existing compressed air delivery components or the same oxygen demand can be met with less air flow. The Slot Injector aerator’s dual flow capability also provides a more diverse operating range to maintain peak aeration efficiency for variable organic loads without sacrificing process mixing.