- Home

- Companies

- Koch-Glitsch, LP

- Products

Koch-Glitsch, LP products

Trays - High Performance Trays

SUPERFRAC - Model XT - High Performance Trays

In larger diameter columns, typical multi-pass designs are limited to four passes. For applications that require more than four passes, the proprietary multi-pass downcomer design can be used to reduce weir loading and improve the capacity of the column.

SUPERFRAC - High-performance Cross-flow Tray

The SUPERFRAC® tray is a high-performance cross-flow tray that has the highest combined capacity and efficiency of all cross-flow trays tested at Fractionation Research, Inc. (FRI) SUPERFRAC trays can be used in new construction and revamp opportunities for virtually any service in which conventional sieve and valve trays are used. They are especially beneficial in applications requiring a large number of mass transfer stages or where mass transfer efficiency is critical to the economics of the operation. Examples include superfractionators (ethylene, propylene), light hydrocarbon fractionators, splitters in chemical and petrochemical applications, and aromatic services.

THORMANN - Tray

The Thormann® tray is designed to handle even the lowest liquid flows, e.g. 40 l/(m2h ) [0.016 gpm/ft2], at a pressure drop as low as 1 mbar per tray. The arrangement of the caps combined with the special vapor slots ensures a controlled flow pattern of the liquid on the tray and consequently a favorable residence time and a high separation efficiency. Liquid weeping is minimized (even under minimum vapor flow rates) and can be completely eliminated by seal welding on installation. The vapor risers are formed from the tray deck and prevent the liquid from leaking down by design, which helps to achieve higher separation efficiency. Optional cooling or heating coils may be provided between the rows of caps for use in, for example, exothermic absorption or reactive distillation applications

Valve Trays

MINIVALVE - Tray Deck

The MINIVALVE® trays produce reduced entrainment and better efficiency than conventional valve tray design and sieve trays. The improvement in capacity can exceed 13% in spray regime services with low-to-moderate weir loadings. MINIVALVE valves exhibit a more uniform froth action on the tray deck compared to full-size valves. They are offered in both fixed (VG-0) and movable (MV-1) styles.

Mass Transfer Equipment - Trays

DEMISTER - Mist Eliminator

Using proprietary design techniques and a wide range of valve types available for FLEXITRAY valve trays, a well-designed FLEXITRAY® valve tray generally provides the most economically attractive solution for your grass-roots column construction projects.

Mist Elimination Equipment - Mist Eliminator

DEMISTER - Mist Eliminators

DEMISTER - Model PLUS - Mist Eliminators

The advanced design DEMISTER-PLUS mist eliminator can achieve even greater increases in capacity over the high capacity DEMISTER mist eliminator. The well-proven DEMISTER-PLUS design features a two-stage mist eliminator, combining the efficiency of the DEMISTER mist eliminator with the high throughput capacity of the FLEXICHEVRON vane-type mist eliminator or cyclone mist eliminator.

FLEXICHEVRON - Conventional Mist Eliminators

FLEXICHEVRON mist eliminators collect essentially 100% of all particles greater than 8 to 40 microns in diameter, depending on design parameters and operating conditions. These mist eliminators are baffle or zigzag blade modules tailored for either vertical or horizontal flow installations. Manufactured in virtually any size from a wide range of metal alloys, thermal-set plastics and fiber-reinforced plastic (FRP), over 20 different styles can be designed and fabricated. Koch-Glitsch offers many types of chevron mist eliminators for the numerous styles of absorbers and internal support arrangements.

FLEXICHEVRON - High Capacity Mist Eliminators

FLEXICHEVRON styles 250 (horizontal) and 350 (vertical) mist eliminators can efficiently remove droplets smaller than 10 microns in diameter in clean service even at higher pressures. Style 250 and 350 designs rely on separate liquid drainage channels for their high capacity. These designs offer higher allowable velocities and different vane geometries. The unique "double pocket" construction collects liquid flows in separate channels and isolates the liquid from the gas stream. Because the liquid is isolated from the gas stream and less subject to re-entrainment, gas velocities can be more than doubled in both horizontal and vertical gas flow configurations.

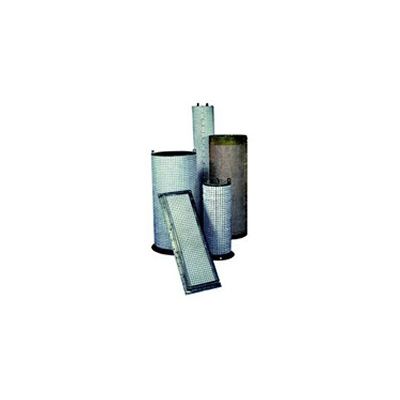

FLEXIFIBER - Mist Eliminators

Depending on the design parameters, FLEXIFIBER® mist eliminators collect up to 99.95% or greater of all submicron liquid particles.

FLEXIFIBER mist eliminators consist of a packed fiberbed between either of two concentric screens or two parallel screens. Koch-Glitsch offers three types of FLEXIFIBER mist eliminators that are based on the type of mechanism for separation: