Komline-Sanderson products

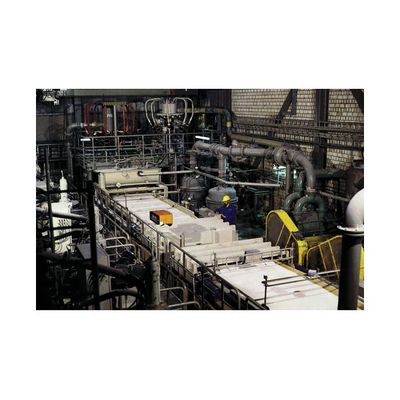

Biosolids/Sludge Dryer

Komline-Sanderson - Paddle Dryer for Biosolids, Sludge and Residuals Drying

The K-S Paddle Sludge Dryer is used worldwide for drying a variety of sludges, biosolids and by-products, to generate dry stable products, reduce disposal cost and convert waste into marketable by-products. In municipal waste water treatment plants (MWWTP) the K-S Paddle Sludge Dryer System produces Class A Biosolids in accordance with the EPA’s 503 regulations allowing the dried granular material to be used beneficially as a slow release fertilizer or soil amendment. Dried waste products have also been used as fuel in boilers and cement kilns.

Paddle Dryer/Processor

Komline-Sanderson - Paddle Dryer and Paddle Processor

The Komline-Sanderson Paddle Dryer and Paddle Processor are highly efficient, mechanically agitated, indirect heat transfer devices that add or remove heat from a process mass. They are used for indirect drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.

Belt Filter Press

Komline-Sanderson Kompress - Model Series III - Belt Filter Press

The Komline-Sanderson Kompress Belt Filter is a broadly applicable product for dewatering municipal Biosolids and industrial sludges.

Gravity Belt Thickener

Komline-Sanderson Gravabelt - Gravity Belt Thickener

Gravabelt Gravity Belt Thickeners reduce sludge volume of biosolids and waste activated sludge and produce a pumpable concentrate for dewatering, transport, or further digestion. The K-S Gravabelt uses only gravity and a porous drainage belt along with our Roto-Kone High Rate Drainage system to enhance thickening performance at a reduced operating cost.

Screw Press

Komline-Sanderson - Multi-Wave Screw Press

Komline-Sanderson’s Multi~Wave Screw Press is designed to obtain high volume reduction and high hydraulic throughput at a low polymer dose. The design provides for low maintenance costs and long operational life in the highly corrosive atmosphere of sludge treatment. As a thickener and dewatering device combined in one unit, polymer consumption is reduced because progressive stabilization is achieved through the aggressive removal of water in the thickening zone. The unit self-regulates to achieve the highest cake solids in one step.

Vibrating Fluid Bed Dryer

Komline-Sanderson - Model VFBD - Vibrating Fluid Bed Dryer

The Komline-Sanderson Vibrating Fluid Bed Dryer (VFBD) is a direct drying system used to thermally process a wide variety of materials. The VFBD uses direct heat transfer to process many different pastes, cakes, powders, and granules in a highly controllable manner. In addition, the VFBD “fluidizes” the material by a combination of vibration and air that passes upward through it, allowing for uniform heat and mass transfer.

Rotary Drum Vacuum Filter

Komline-Sanderson - Rotary Drum Vacuum Filters

Komline-Sanderson continuous rotary drum vacuum filters for the separation of liquids from solids offer great flexibility in meeting the needs of many industries. Our experience ranges from simple separations to complex multi-stage applications involving filtration, clarification, extraction, cake washing, and drying.

Horizontal Vacuum Filter

Komline-Sanderson - Model CIX - Horizontal Vacuum Filters

The K-S CIX Horizontal Vacuum Filter is a top fed filter that can perform filtration, extraction, and drying in one machine. Slurry is fed continuously and forms a filter cake, which can then be washed as it is progressively indexed through discrete zones. Slurry is fed continuously and forms a filter cake, which can then be washed as it is progressively indexed through discrete zones. It is ideal for applications requiring counter current washing and precise separations.

Dissolved Air Flotation

Komline-Sanderson - Dissolved Air Flotation Clarifier

Komline-Sanderson Dissolved Air Flotation Clarifier is suited for wastewater streams containing solids, oils, and greases, which are difficult to settle or have a tendency to float. With proper chemical conditioning we remove colloidal and emulsified materials. Complete pretreatment systems can be supplied.

Rotary Atomizer

Komline-Sanderson - Rotary Atomizer System

Komline-Sanderson’s variable-speed Rotary Atomizers represent a dependable approach to atomization and spray drying. The compact, rugged, direct-drive, high-speed motor, utilizing only a few parts in one rotating assembly (no gear, pulley, gearbox or coupling), reduces the need for traditional mechanical maintenance. High quality, oil-mist lubricated precision bearings (ABEC-7), of ceramic-ball design, provide maximum reliability for flue gas desulfurization or spray drying applications. Our Rotary Atomizer units can handle any pumpable feed material, solution or slurry, covering a wide range of feed characteristics in terms of solids content, density, and viscosity. Process material can be fed to the atomizer by a low-pressure positive displacement pump, or even by gravity flow from a head tank. The atomizer converts the feed into a spray or atomized cloud of fine droplets, typically 30-50 microns in size, suitable for spray drying.