Kontek Ecology Systems Inc. products

Specialty Products - Process Bath Purification - KC- Series Process Bath Purification

Kontek Ecology - Single Column Ion Exchange System

This unit is typically used for tri-chrome bath tank sizes up to 200 USG, subject to confirmation of the tramp metals loading rates. One seal-less magnetically coupled pump with priming chamber & pump discharge pressure. One polypropylene filter chamber capacity (1) 30” DOE filter cartridge to prevent fouling. One flow meter with a needle valve to accurately control the flow of process solution, regenerant chemical and rinse water through the resin bed. One 36” resin column each build-in resin screen to contain the resin, and constructed of polypropylene and acrylic.

Kontek - Double Column Ion Exchange System

This unit is typically used for tri-chrome bath tank sizes up to 600 USG, subject to confirmation of the tramp metals loading rates. One seal-less magnetically coupled pump with priming chamber & pump discharge pressure. One polypropylene filter chamber capacity (1) 30” DOE filter cartridge to prevent fouling. Two flow meter with needle valve to accurately control the flow of the process solution, regenerant chemical and rinse water through the column. Two 36” resin columns each build-in resin screen to contain the resin, and constructed of polypropylene and acrylic.

Kontek - Triple Column Ion Exchange System

This unit is typically used for tri-chrome bath tank sizes up to 800 USG, subject to confirmation of the tramp metals loading rates. One seal-less magnetically coupled pump with priming chamber & pump discharge pressure. One polypropylene filter chamber capacity (1) 30” DOE filter cartridge to prevent fouling. Three flow meters with a needle valve to accurately control the flow of the process solution, regenerant chemical and rinse water through the column. Two 36” resin columns each build-in resin screen to contain the resin, and constructed of polypropylene and acrylic.

Kontek - Quad Extended Column Ion Exchange System

This unit is typically used for tri-chrome bath tank sizes up to 1,000 USG, subject to confirmation of the tramp metals loading rates. One seal-less magnetically coupled pump with priming chamber & pump discharge pressure. One polypropylene filter chamber capacity (1) 30” DOE filter cartridge to prevent fouling. Four flow meters with needle valve to accurately control the flow of the process solution, regenerant chemical and rinse water through the column. Two 40” resin columns each build-in resin screen to contain the resin, and constructed of polypropylene and acrylic.

Specialty Products - Zero Liquid Discharge (ZLD) Boosters

Kontek ConRec - Filter Press for Zero Liquid Discharge Boosters

Filter Presses Designed for Long-Term Rugged Use. Reduce the solids dewatering costs and solid waste volume. Quickly transform the fluid waste stream into a solid state that will pass the slump test. Filter Presses consistently transform a liquid solution containing 2% to 5% of suspended solids into solid sludge cakes with 30% to 35% of solids content for easy disposal. Paired with a ConRec sludge dryer, the filter press is an important step in achieving Zero Liquid Discharge (ZLD). Minimize operator attention and let gravity do the work for you. Positioned over the dryer, the press will automatically unload sludge cakes when the press cycle is complete.

Kontek ConRec - Sludge Dryer for Filter Press Systems

Minimize your filter press sludge disposal volumes to less than 25%. ConRec Sludge Dryers provide a full range of capacity, they are designed for small, medium and high sludge volumes. We build each unit to fit under the Filter Press to eliminate hazardous sludge handling, this enables efficiently semi-continuous batch sequencing, reducing volume and space of the sludge. Even in small plating shops, sludge disposal costs can add up to big money. Now there is an affordable solution. The ConRec Sludge Dryer is now available from two to six cubic foot capacities, to meet the needs of shops and departments where large dryers are not necessary, or from eight to hundred cubic foot to handle large sludge requirements.

Kontek ConRec - Liquid Crystallizer for Zero Liquid Discharge Boosters

The final step for your Zero Liquid Discharge (ZLD) Operation. Perfect for low-volume, corrosive liquids solutions, ConRec Liquid Crystallizer quickly removes moisture content, leaving behind crystallized salts for disposal. With a trustworthy design that’s been used in the industry for over 25 years, the Liquid Crystallizer eliminates contaminated haulage and disposal costs. ConRec Liquid Crystallizer reduces liquid content by 90%, leaving only the dissolved salts remaining as dry powders with significantly lower disposal costs.

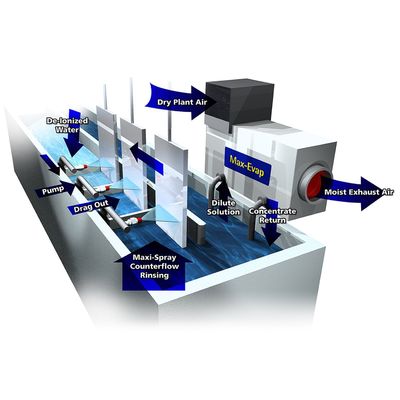

Kontek Max-Evap - Atmospheric Evaporator

Drive down costs and reclaim drag-out while maintaining consistent solution concentrations with Max-Evap. Using atmospheric evaporation, Max-Evap protects your plating bath chemistry, prevents solution growth, and reduces your wastewater production rate. Max-Evap atmospherically evaporates water by taking advantage of airu2019s ability to absorb water from your process solution, while leaving valuable salts behind. Max-Evap evaporation produces a refrigerating effect, which cools the solution. After evaporation, Max-Evap discharges two streams: moisture-rich air and a concentrated liquid chemical stream that is returned to the plating bath.

Specialty Products

Kontek - Water Conservation Solution for Plating Rinse

Reduce or eliminate drag-out while minimizing the amount of rinse water your process requires. Maxi-Spray discharges a powerful flat-knife spray that quickly removes impurities on the parts between bath dips. Using a sustainable counterflow design, the Maxi-Spray conserves water by pumping solution from the next upstream rinse tank in line.

Technologies

Kontek ROKON - Reverse Osmosis Purification System

Purify And Recover Up To 90% Of Your Wastewater. Designed for ultra-efficiency, Kontek`s ROKON Reverse Osmosis Systems recover up to 90% of raw city water or recovered process feed water. Our highly efficient membranes and optional variable speed drives will minimize your facilities` energy requirements. Systems are controlled by PLC-driven operator interfaces, which display and archive all important system information on a user- friendly control panel. Premium instrumentation package offers industry-leading membrane protection. Every ROKON Reverse Osmosis System is mounted on a powder-coated or stainless-steel rugged frame designed to withstand harsh environmental conditions. Kontek only uses the highest quality pumps, membranes, and instrumentation, with proven performance and durability.