Kyoto Technology Italia products

Engine Crushers

Kyoto - Engine Crusher

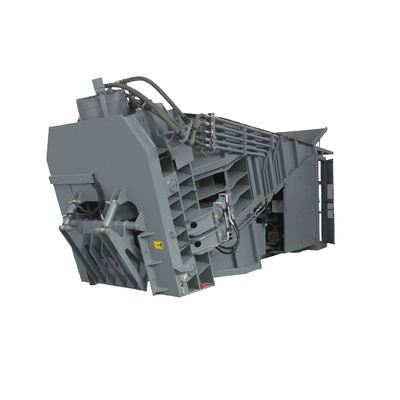

The SM 160 Engine Breaker is more powerful, performant and larger than the previous SM 140, it is designed and built to easily crush transmissions, gearboxes and endothermic engines even of large dimensions as truck engines, making it easy and fast to collect and separate the metals of which they are composed (copper, aluminium, steel, iron etc.) thus increasing their exploitation. The robust structure is made of S355J2G3 steel; the compression case made entirely of fully replaceable wear-resistant Hardox 400 steel sheets. The simplicity of use, simple maintenance and low operating costs make it an indispensable equipment.

Horizontal Shears

Kyoto - Horizontal Cutting Shear

Designed to complement the range of traditional shears, the HS 1000 horizontal shear offers equivalent performance with small dimensions. The HS 1000 is able to easily handle ferrous and non-ferrous scrap, even large-sized thanks to the additional hopper that allows you to shear pipes, beams and tubes longer than 5 meters without difficulty. Powered by two electric motors and continuously charging operation: the scrap is loaded into the hopper where it slides by gravity into the compression chamber, is compressed and falls into the cutting chamber to be sheared while the operator can feed new scrap into the hopper; it is capable of shearing up to 18 t/h of scrap.

Kyoto - Detachable Horizontal Shear

Designed to complement the range of traditional shears, the CS 1000 horizontal shear offers equivalent performance, with small dimensions and the possibility of being moved and/or transported to a construction site in a few minutes with the sole aid of a vehicle with a detachable system.

Kyoto - Horizontal Shear

The HS 400 horizontal shear is designed to easily shear ferrous and non-ferrous light and medium collection materials such as round bars, pipes, beams, etc. The difference between the HS 400 and the other shears is the final result: the output material is cut into extremely small pieces (300x300x300), due two lateral pressers that compress the material before shearing, thus increasing its valorisation. The simplicity of use, easy maintenance, thanks to the power-pack in a separate unit, and the low operating costs make it an equipment with an excellent cost /productivity ratio.

Inclined Shears

Kyoto - Inclined Shear

The CI series of inclined shears are ideal machines for processing and recycling medium and heavy waste. Thanks to the large loading tank and the rear swing slide, it is ideal for handling long materials such as beams, pipes, sheet metal and scrap, usually up to 14 m in length.

Kyoto - Inclined Shear

The “CI” series of inclined shears are ideal machines for industries and for recycling medium and heavy waste. Thanks to the large loading tank, it is the ideal machine for handling long materials such as beams, rails, pipes, sheet metal and scrap in general without length limitations.

Press Compactors

Kyoto - Press Compactor

Kyoto - Press Compactor

Shear Shredder

Kyoto - Shear Shredder

With S355 J2 G3 carbon steel this machine has got a working temperature of -20° C. The machine may be equipped with electric motor instead of diesel engine.