Linn High Therm GmbH products

Resistance Heating - Batch - Front Loader

Model AK-MODEL - Chamber Furnace For Annealing

CHAMBER FURNACE FOR ANNEALING, BRICK AND ASW INSULATION, TMAX 800 °C, 22 - 603 L. Applications: annealing, curing, drying, heat treatment, oxydation, pre-heating, shrink fitting, stress-relieving, tempering

Induction Heating - High Frequency Generators

Model HTG-N-MODEL - High Frequency Generator

Applications: borating, calibration, casting, crystal growing, CVD chemical vapour deposition, forging, fusion, gemstone heat treatment, glueing, graphitization/carbonisation, hardening, heat treatment, levitation melting, melting, pre-heating, pulling, remelting, sample preparation for spectroscopy, shrink fitting, soldering, surface coating, tempering

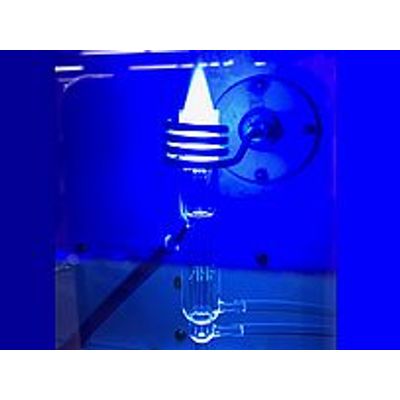

ICP Generator

ICP GENERATOR FOR ANALYZING OF LIQUIDS (ICP-OES AND ICP-MS) FOR ARGON / ARGON OR ARGON / NITROGEN PLASMA. FREQUENCY RANGE 1,5 - 2,5 KW, 27,12 / 40 MHZ AND 1,5 - 10 KW, 27,15 MHZ.

Microwave Heating - Laboratory Units

Model MKE-MODEL - Microwave Chamber Furnace

MICROWAVE CHAMBER FURNACE, HIGH TEMPERATURE, 2.45 GHZ, 3.0 L, TMAX 1200 °C. Applications: ashing, calcination, melting, sintering

Resistance Heating

Model LM - Laboratory Muffle Furnace

Laboratory Chamber Furnace, ASW Insulation, TMAX 1340°C, 1,5 - 18,4 L. APPLICATION Laboratory muffle furnaces for all applications up to 1200 °C. Standard controller Jumo: PID controller with one free programmable heating ramp. Option: Controller SE 40 Li with 25 programs each 25 steps. Temperature increase to Tmax 1340 °C for LM 312, LM 412 and LM 512. (LM 112 up to 1200 °C only). Tilting device for LM 112. Exhaust device, gas flushing, post combustion burner.

Model AK - Chamber Furnace

Chamber furnace for annealing, brick and ASW insulation, Tmax 800 °C, 22 - 603 l

Model FBV/GBV - Chamber Furnace

Chamber furnace, bottom loader, PCW-insulation, high temperature, gastight, Tmax 2400 °C, 2-1000 l

Induction Heating

Model HTG-N - High Frequency Generator

Resonant high frequency power supply using Power MOSFET and special frequency and power sensing technology for fast precise induction heating. Due to the compact design the unit is especially suitable to be used in laboratories and industries for installation in automatic machines, assembly lines and machinery. Suitable for all kinds of inductive heating such as hardening, soldering annealing, welding, melting, levitation melting, even in vacuum containers. Suitable for induction coils between 0,3 and 2,2 µH. Control unit with separate RF/HF-part (cable length 2,5 m). HF/RF-output galvanically separated from mains.

Lifumat Combi - Remelting and Fusion Unit

Remelting and Fusion unit for sample preparation for spectroscopy (XRF, ICP, AAS, X-Emission) and scrap recycling, vacuum and gastight, 3.3 kW

Lifumat-Met - Remelting Unit

Remelting unit for sample preparation for spectroscopy (XRF, ICP, AAS, X-Emission) and scrap recycling, gas and vacuumtight. 3.3 - 30 kW