Logical Clean Air Solutions products

Products

Flow-Through Substrates & Catalysts

Logical Clean Air Solution`s Substrates are extruded honeycomb monoliths containing thousands of parallel channels. The channel walls are coated with precious metal catalysts that convert noxious emissions into less harmful gases and water vapor. Ceramic substrates are used at the heart of catalytic converters to help reduce exhaust emissions from Diesel and gasoline-powered engines. Our Ceramic substrates and filters are used around the world in diverse applications across the pollution abatement industry to help customers achieve efficiencies, reduce particulate matter, and improve performance in new and retrofit stationary emissions control systems.

wall-flow Diesel Particulate Filters

Our diesel particulate filters utilize Advanced Cordierite or Aluminum Titanate wall-flow monoliths to trap the soot produced by diesel engines. The cylindrical filter element consists of many square parallel channels running in the axial direction, separated by thin porous walls. The channels are open at one end, but plugged at the other. This way the particle laden exhaust gases are forced to flow through the walls. Gas is able to escape through the pores in the wall material. Particulates, however, are too large to escape and are trapped in the filter walls.

Flow-Through Diesel Oxidation Catalyst

The diesel oxidation catalyst (DOC), or Two-Way, owes its name to its ability to promote oxidation of several exhaust gas components by oxygen, which is present in ample quantities in diesel exhaust. When passed over an oxidation catalyst, the following diesel pollutants can be oxidized to harmless products, and thus can be controlled using the DOC: Carbon monoxide (CO), gas phase hydrocarbons (HC), organic fraction of diesel particulates (SOF). Additional benefits of the DOC include oxidation of several non-regulated, HC-derived emissions, such as aldehydes or PAHs, as well as reduction or elimination of the odor of diesel exhaust.

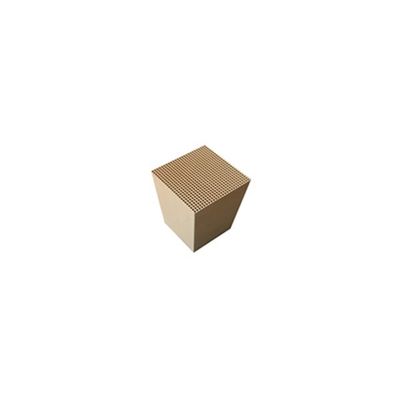

Stationary Flow-Through Substrates (Catalyzed or Uncatalyzed)

Examples of Non-Road (Stationary) Emissions Applications: Hot Gas Filtration, Cloud Chamber, Industrial Boilers, Dust Collectors, NOx Scrubbers, Incinerators, Power Plans, Steel Mills, Smelters, Cement Plants, Oil Refineries, Printing or paint Shops.

SCR, NSCR & Pre-Extruded SCR Catalysts for Emission Control

Logical Clean Air Solutions provides SCR, NSCR, and Pre-Extruded SCR Catalysts for Emission Control Manufacturers to reduce cost and improve quality of systems. We offer ceramic honeycomb SCR catalyst for the power generation, petro-chemical and industrial processing industries worldwide.

Customized Ceramic Filters

For those large applications that require filter diameters over 13", we have customized filter options for you. Logical Clean Air Solutions offers made-to-order substrates and diesel particulate filters for use in various emission applications.

Solutions

Three-Way Catalytic Converters

3-Way Catalytic Converters control exhaust emissions from stoichiometric CNG, LPG and gasoline engines. 3-Way catalytic converter technology cannot be used on lean-burn CNG or diesel engines (see SCR for diesel NOx control). Three-way catalytic mufflers are the most effective way of controlling carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) emissions with simultaneous reductions of up to 90-99%.

Diesel Retrofit Systems

Logical Clean Air Solutions has partnered with over 160+ emissions equipment manufacturers for advanced engineering, prototyping, and manufacturing of Diesel Retrofit Systems. These systems can be retrofitted on trucks and buses, off-highway vehicles, and stationary diesel engines. We find the most cost effective way to reach your emissions regulations.

Selective Catalytic Reduction (SCR`s)

An SCR system is a reliable, cost-effective technology designed to control nitrogen oxides (NOx) emissions from medium and heavy-duty diesel engines in on-road, non-road and stationary applications.

Regenerative Catalytic Oxidizer (RCO) & Regenerative Thermal Oxidizer (RTO)

A Regenerative Catalytic Oxidizer (RCO) & Regenerative Thermal Oxidizer (RTO) destroys Hazardous Air Pollutants (HAPs), Volatile Organic Compounds (VOCs) and odorous emissions that are often discharged from industrial processes. The RCO achieves emission destruction through the process of thermal and catalytic oxidation, converting the pollutants to carbon dioxide and water vapor while reusing the thermal energy generated to reduce operating costs. What differentiates the RCO from a standard RTO system is the addition of catalyst. It allows destruction of harmful compounds to occur at lower temperatures.