- Home

- Companies

- Logical Clean Air Solutions

- Products

- Flow-Through Substrates & Catalysts

Flow-Through Substrates & Catalysts

Logical Clean Air Solution`s Substrates are extruded honeycomb monoliths containing thousands of parallel channels. The channel walls are coated with precious metal catalysts that convert noxious emissions into less harmful gases and water vapor. Ceramic substrates are used at the heart of catalytic converters to help reduce exhaust emissions from Diesel and gasoline-powered engines. Our Ceramic substrates and filters are used around the world in diverse applications across the pollution abatement industry to help customers achieve efficiencies, reduce particulate matter, and improve performance in new and retrofit stationary emissions control systems.

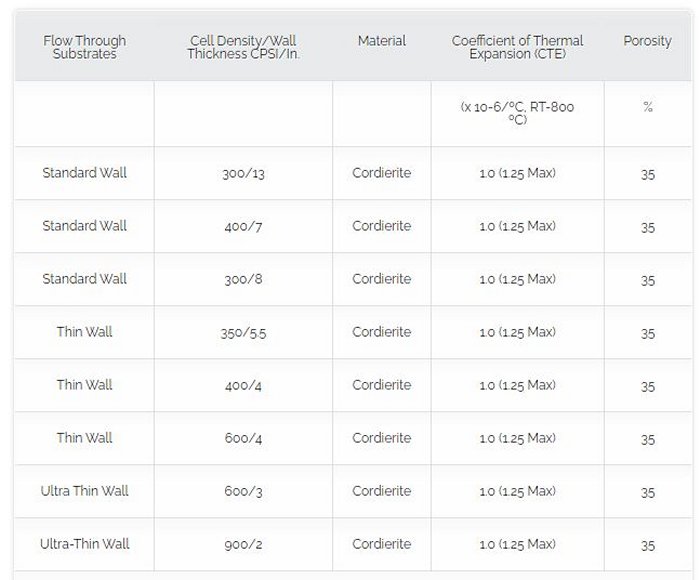

Our products are available in cell densities, diameters and lengths that are among the most diverse in the industry.

Our substrates enable highly efficient emissions control systems by offering:

- High surface area

- Low pressure drop

- Rapid light-off

- Thermal-mechanical durability

- System cost efficiency

Exhaust gases can reach extreme temperatures and are highly variable, producing thermal stresses within the converter. The ceramic composition used in our substrates is highly resistant to thermal shock resulting from sudden and severe temperature changes. In addition, these advanced substrates can operate effectively at temperatures of 1200C and can withstand spikes of up to 1400C.

Cordierite Ceramic Substrates have proven mechanical durability. Their monolithic (single-piece) structure and cellular geometry promote stiffness and isostatic strength.

The higher geometric surface area of Thin-Wall & Ultrathin-Wall substrates contributes to lower emissions during steady-state catalytic converter operation. In addition, their lower mass facilitates quicker converter light off for more effective cold-start emissions reductions.

With their thinner walls, Thin-Wall & UltraThin-Wall substrates also offer the option of improved pressure drop performance. Compared to a 600/4 thin-wall substrate, and Ultrathin-Wall 600/3 substrate delivers approximately the same geometric surface area with 10% lower pressure drop.