Metalfab Material Handling Systems, LLC products

Bin Activators

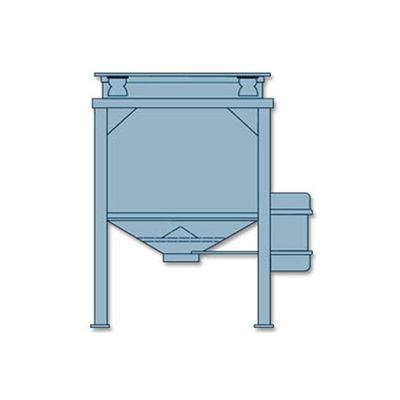

Metalfab - Standard Bin Activators

The tendency of dry solids to flow from bins in a sporadic or irregular fashion has perplexed the materials handling industry from its earliest days. Attempts to solve the problem have ranged widely - and wildly - from the use of a laborer with a sledge hammer, to rappers or vibrators and powerful blasts of air. Over the years no single method or combination of techniques ever provided a universally successful solution. Then in 1960, a revolutionary new concept was introduced which overcame the troublesome and costly problems of arching, bridging, and rat-holing. Called a "Bin Activator", the device consisted of a vibrated cone which was suspended beneath the bin, replacing a major portion of the standard fixed cone. Positive discharge was achieved through the successful application of the principles of vibration as well as by the design of the unit.

Metalfab - Sanitary Bin Activators

Metalfab`s Sanitary Bin Activators feature the same rugged, durable, long lasting construction and unique operating features found in our standard steel bin activator line. However, a number of added features make our sanitary bin activators suitable for food applications - including continuous internal welds ground smooth, all contact surfaces polished, secondary baffle support without threads, primary baffle raised 2" off the cross members, round cross members with enclosed corners, white neoprene main sleeve and "bead blasted" exterior steel surfaces.

Posibins & Bins

Metalfab - Posibin

The Metalfab Posibin provides positive, problem-free discharge from storage of a wide range of difficult to handle materials - in a variety of densities and particle sizes. From micron-size powders to fibrous substances, materials flow freely, on demand, on a first-in, first-out basis.

Metalfab - Live Bin- Round Metal Live Bin with Baffle

The Metalfab Live Bin consists of a round metal bin with a single baffle supported immediately above the outlet. The bin and its entire contents are vibrated horizontally in response to the forces of the unbalanced weights of the vibrator. The Live Bin comes with its own support frame and, like the Bin Activator and the Posibin, the Live Bin will insure the uninterrupted flow of material upon demand without bridging or rat holing. Metalfab Live Bins are ideally suited for both sanitary and pressure applications since there is no gap to close between a non-vibrated and a vibrated section. Sizes range from 3 cu. ft. to 100 cu. ft. capacities.

Gravimetric Feeders

Better Weigh - Continuous Weigh Feeders

Continuous Weigh Feeders For highly accurate, gravimetric feeding of dry bulk materials in batch or continuous operation. Better-Weigh®` Batch/Continuous Weigh Feeders are designed to provide feeding in either batch or continuous mode depending upon the arrangement of the feeder`s control electronics. In batch mode, the batch controller is used to control the fast (bulk) and slow (dribble) speeds of the feeder. Accuracies of ±0.5% can be easily achieved in 2 lb. or less batches, and ±0.25% with 3 lb. or greater batches with time spans of 30 to 90 seconds. In continuous mode, the feeder`s electronic controller is used to constantly monitor loss-of-weight of material per time in order to maintain a continuous loss-of-weight with an accuracy of ±0.25% to 0.50%.

Volumetric Feeders

Metalfab- MetaTech - Screw Feeders

Metalfab MT MetaTech Screw Feeders for simple, economical, & highly reliable feeding of dry bulk materials. Metalfab`s ruggedly built MetaTech Feeder features a compact, space-saving design, low maintenance direct drive, and new Delrin® bushing for highly accurate and dependable metering of powders, pellets, flakes, and agglomerates.

Conveyors

Metalfab - Flexible Screw Conveyor

Metalfab Convey-All/FSC Flexible Screw Conveyors feature a rugged modular design and provide a highly effective yet economical means to convey powder or granular material without product separation. Conveyors are available in configurations from 10 to 20 ft. lengths with a choice of a 3` diameter helix screw rated to convey up to 150 cu. ft./hr. or a 4` diameter helix screw rated to convey up to 450 cu. ft./hr. Engineered with only one moving part, the conveyors are economical to use, easy to clean, and simple to maintain with virtually no process downtime.

Other Products

Metalfab - Bulk Bag Unloaders

Metalfab Bulk Bag Unloaders are designed and engineered to provide a dependable, low cost means for emptying a wide variety of powders and other difficult to handle dry bulk materials. Metalfab also manufactures other special units for heavier bags, larger bags, or smaller bags.

Metalfab - Bag Dump Hopper

The Bag Dump Hopper provides a quick, easy and virtually dust free way of dumping and filling your process system with material received in paper bags. The design incorporates a baffle and bin vent (to attach to a central dust collector) or optional bin vent filter over the dump area to maintain a dust free worker environment while providing a fast and effective means to charge your process.